EXPLORE THE CAPABILITIES

GET STARTED TODAYACCURACY, PRECISION & EFFICIENCY

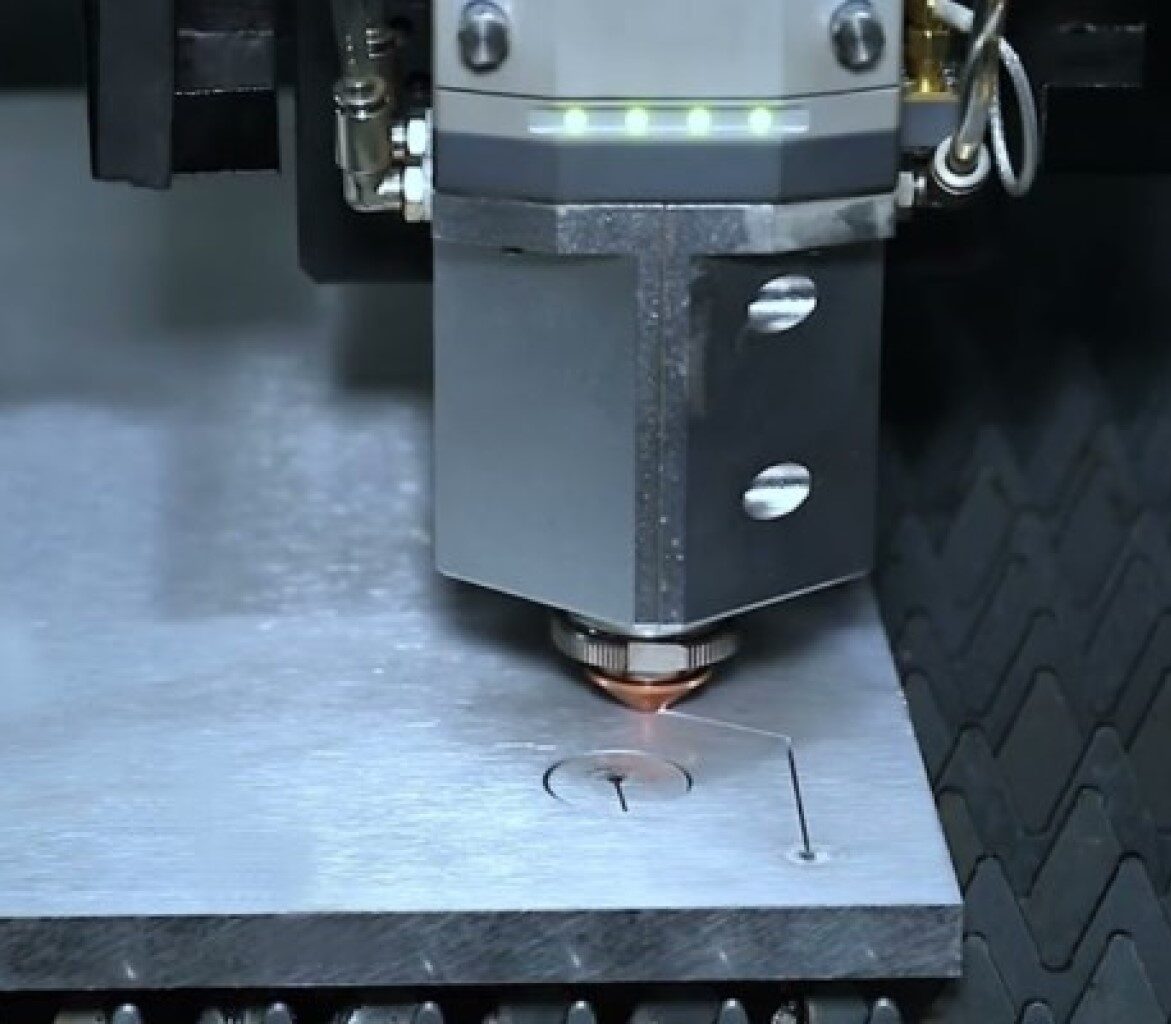

Our Fiber lasers operate 5-10 times the speed of a typical CO2 laser. In addition, the operating cost savings are less than half that of CO2 laser. However, several of our facilities utilize both Fiber & C02 technologies due to the edge quality of the C02 on thicker materials. Also, the CO2 lasers provide greater flexibility on materials. The fiber lasers are used for metals only and are not recommended for non-metals. At the same time, a high-powered CO2 laser can cut both metals and non-metals. The question folks always ask is why have both types, and ultimately, the cost of maintenance & consumables is much less of the fiber, but we get more flexibility on the CO2. Contact FKI today to learn how our laser-cutting services can help your business.

FIBER LASER CUTTING

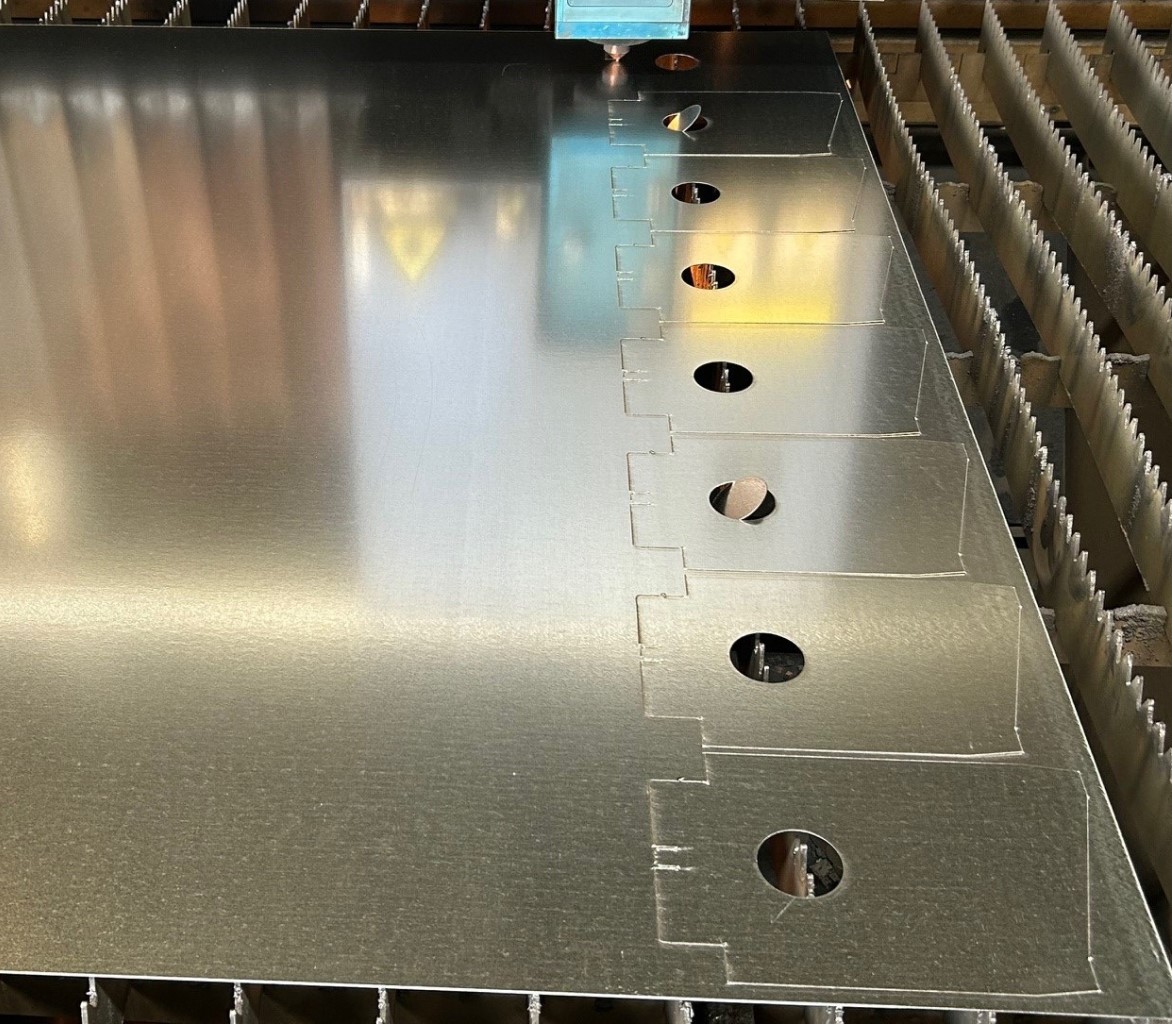

At FKI, we utilize the latest laser-cutting technologies. Our automated laser systems enable us to cut precision blanks, quick-turn prototype blanks, and large-volume production parts. Our largest fiber laser is 12,000 kwh, with a maximum 78″ x 157″ sheet size.

CAPABILITIES

• Precision laser cutting metal ranging up to 78″ x 157″

• Cut Tolerance as close as +/- 0.004”

• Complex shapes and no tooling

• No extended lead time or costs for tooling

• Quick turn prototypes

• Cost-effective manufacturing.

• Burr-free cutting

• Laser beam kerf width = 0.007”

• PVC masking.

HOW IT’S MADE

LASER-CUT PARTS & NO TOOLING REQUIRED

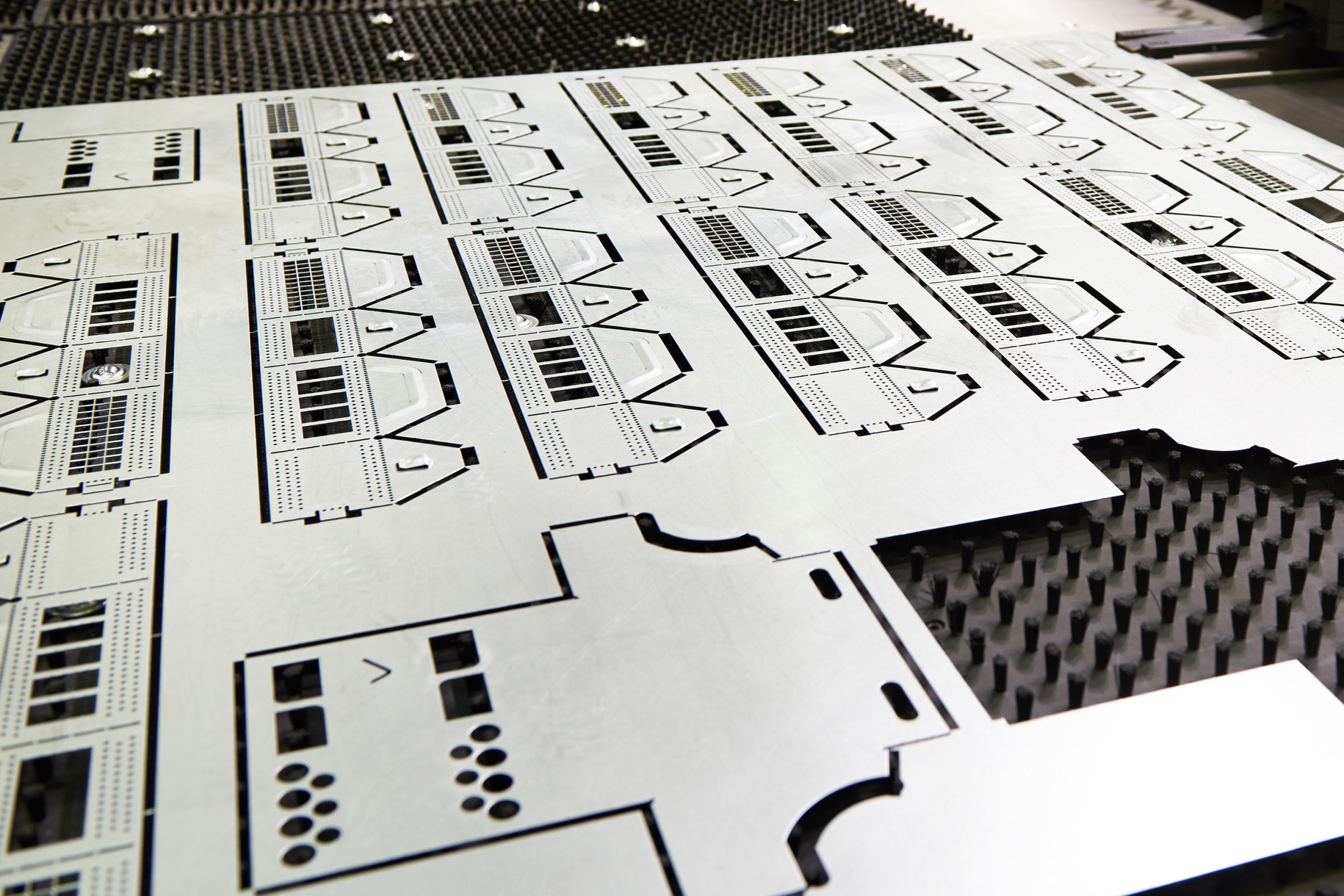

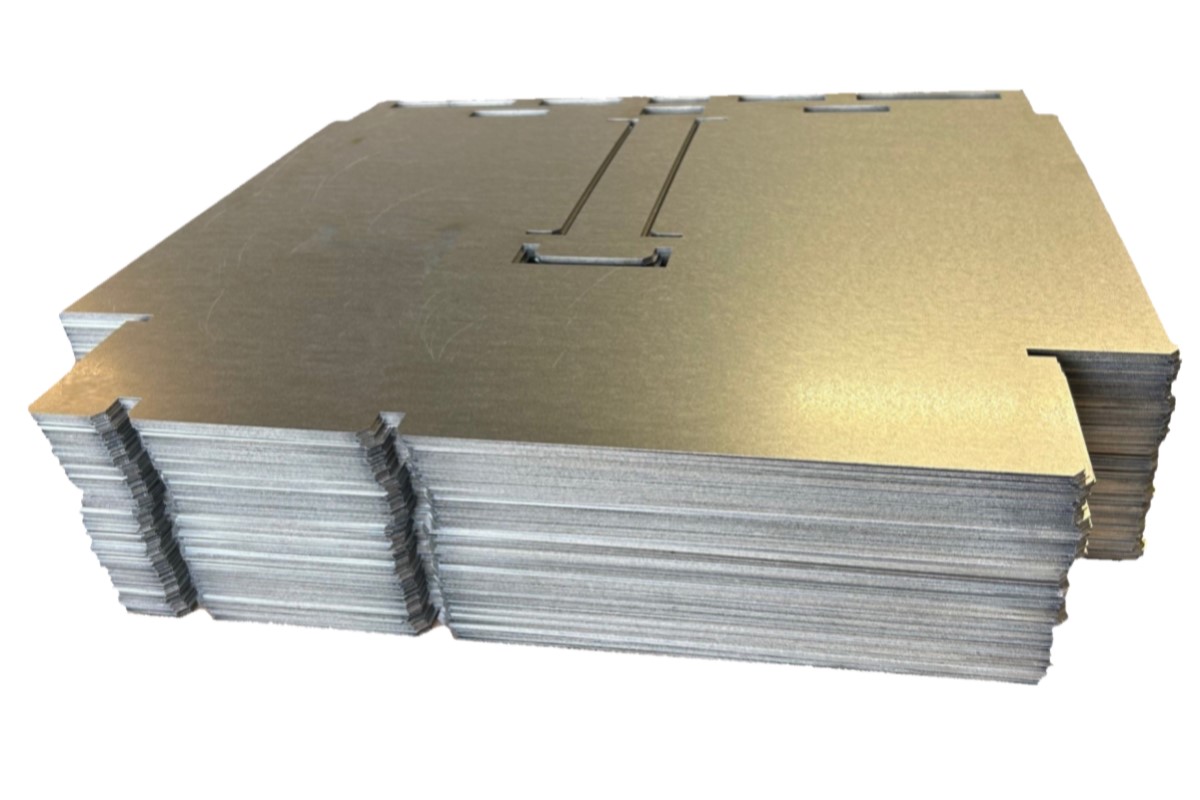

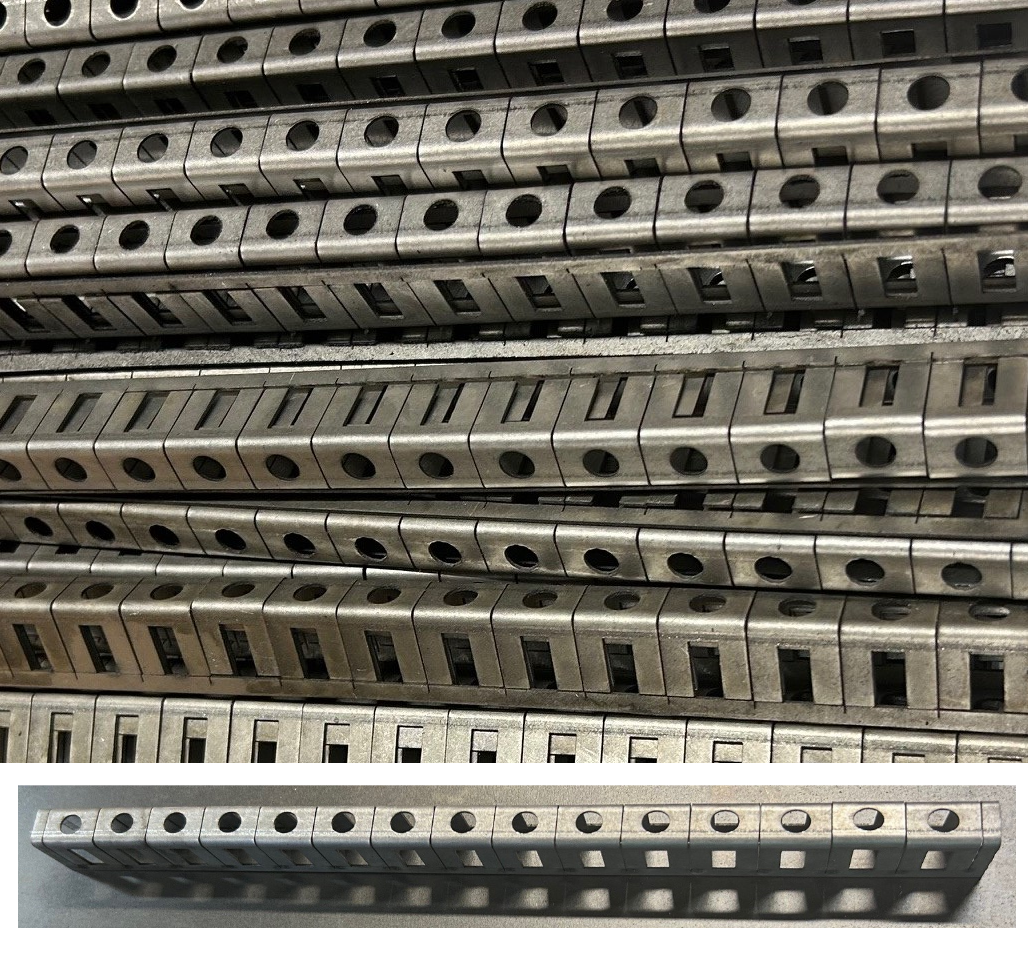

For decades, we have invested significant time, effort, and resources to become an industry leader. From simple to elaborate, we deliver exceptional products at an affordable price. Here is one example where our laser technology and press breaks can save you money. Parts are laser cut from large sheets of flat steel. Each part is held in the laser-cut blank with a small tab. The parts are then “gang” bent on the press break. After bending, each part is easily removed from the tabs. This seems like an easy process, but the parts must be held in the tabs so they don’t shift, and the tabs must be easy to remove; otherwise, productivity suffers. Lastly, the tabs must be small enough to not require secondary deburring.

WATCH VIDEO

THE FKI ADVANTAGE

QUALITY &

CERTIFICATIONS

LEARN MORE

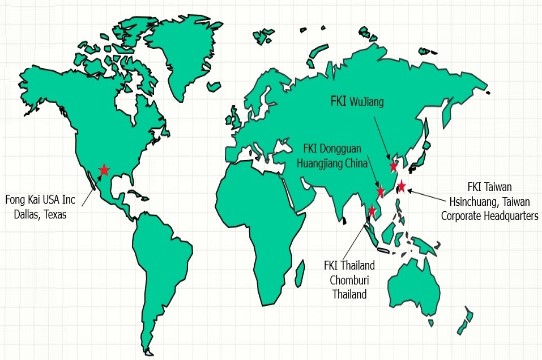

GLOBAL LOGISTICS &

PLANNING

LEARN MORE