EXPLORE THE CAPABILITIES

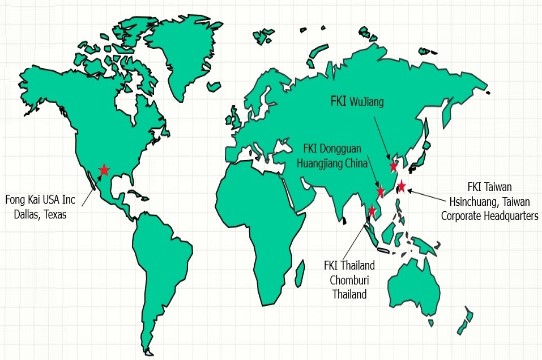

GET STARTED TODAYOur expansive stamping and molding capabilities and experienced team members can support large production volumes and big part sizes that other manufacturers find problematic. By delivering quality products on time and on budget for over forty years, we have become the supplier of choice for many global companies. From simple to elaborate, we deliver exceptional products at an affordable price. Our facilities have the product diversity and manufacturing experience for some of the most prestigious automotive, rail, heavy equipment, and truck manufacturers. In addition, we produce components for many tier 1 and tier 2 customers. Our manufactured components include, but are not limited to:

METAL COMPONENTS

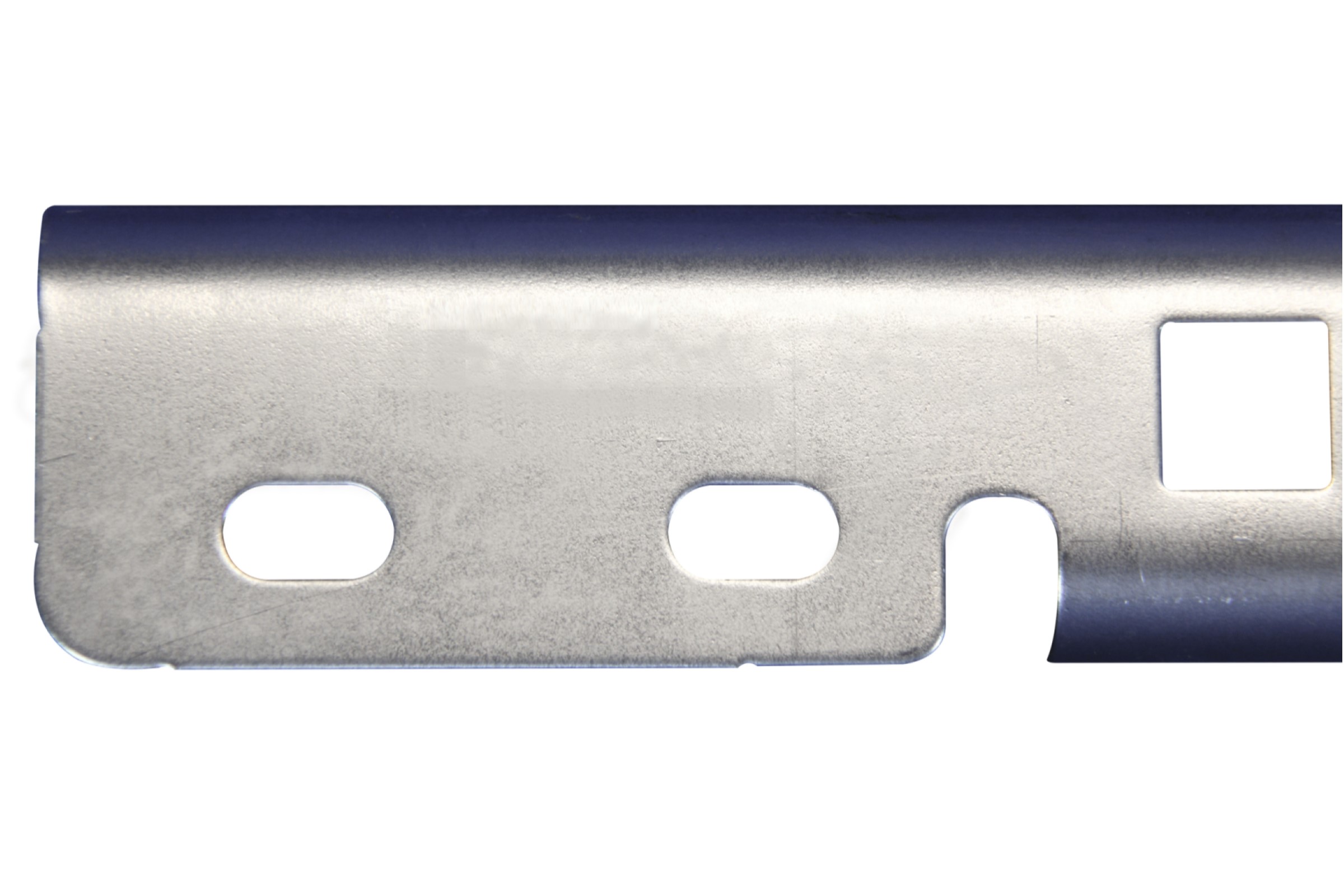

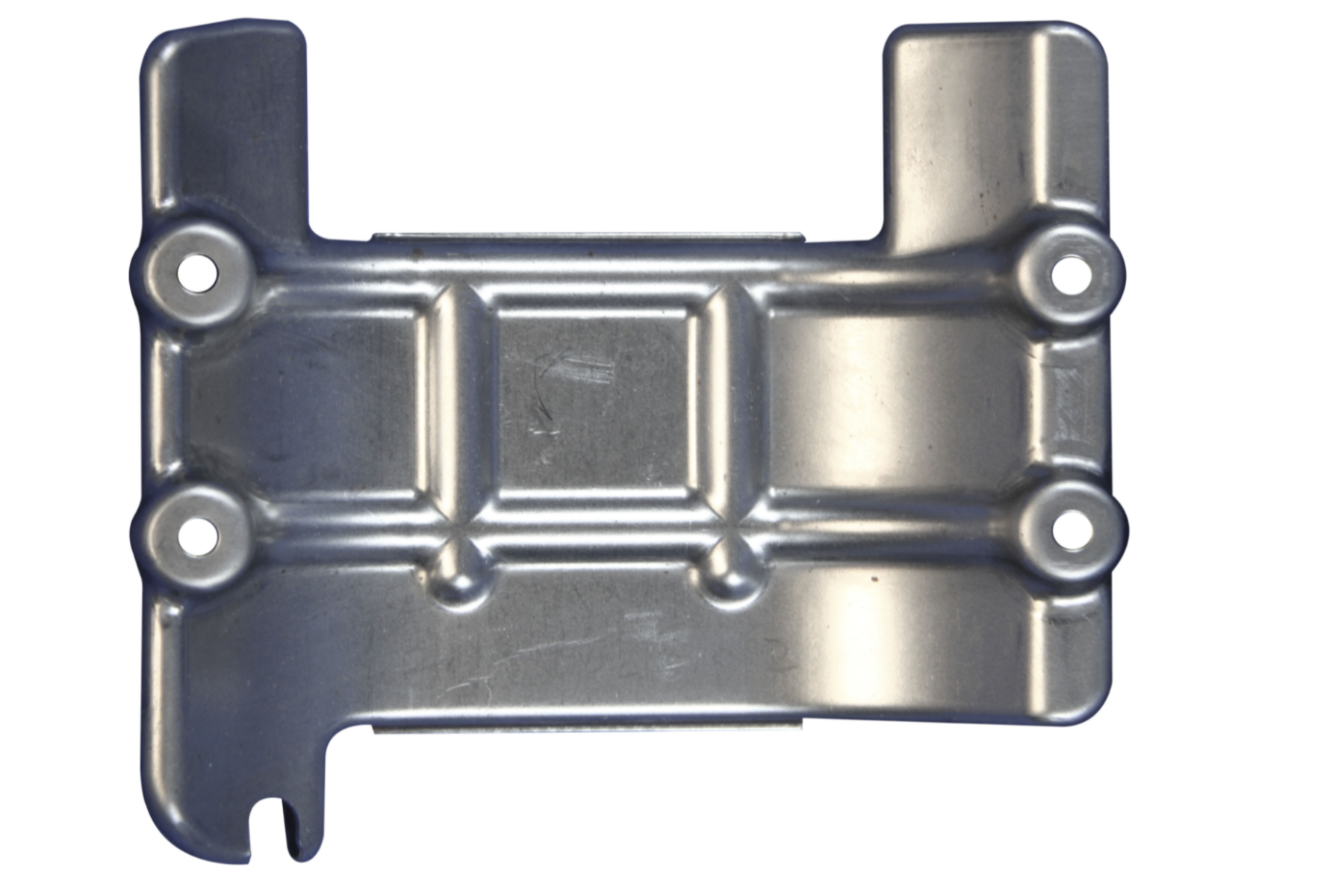

Steel stampings are widely used in the automotive and transportation industries for their strength, durability, and attractive cost. Currently, about 65% of automobile components are stamped metal. Stampings are mainly utilized in chassis, body, drivetrain, and engine components. Stampings improve the performance and aesthetic appeal of many products. We will help you produce a cost-effective, high-quality part that meets or exceeds your needs.

CAPABILITIES

• Over 620 metal stamping presses worldwide.

• 60 Ton up to 2000 Ton

• Presses Beds up to 72″ x 177″

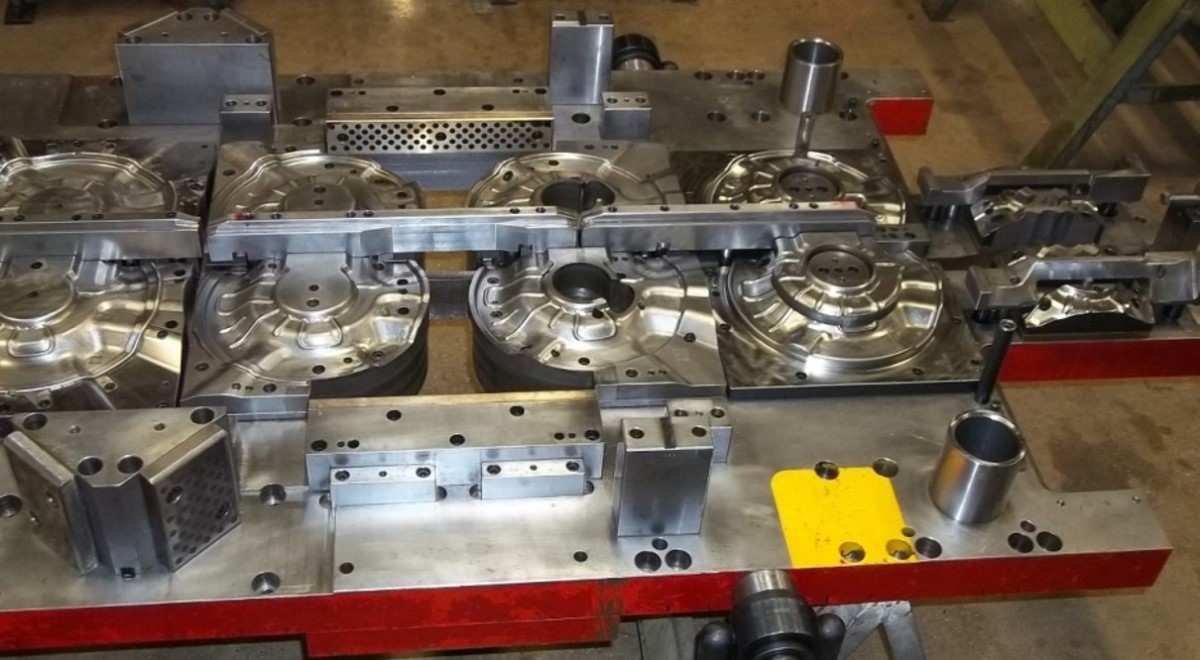

• Progressive & Transfer Stamping

• Class A Cosmetic products

• Specializing in Deep Draw stamping of larger components

• Quality Capable Tooling to support tight tolerances and consistent parts

• In-House Tooling Design, Fabrication and Maintenance

• World-class manufacturing from multiple locations overseas or from our US facility

• All our stamping facilities are certified (ISO 9001) 2015

ADDITIONAL FEATURES INCLUDE, BUT NOT LIMITED TO:

• Robotic Welding, Deburring, Painting Wet and Dry, E-Coating, and PVD Coating

OEM PRODUCTS

• Interior –Brackets, Housings, Seating, Climate Control and Decorative Products

• Structural- A&B Pillars, Liners, Skins and Body Components

• Suspension and Steering -Brake Shields, Actuators, Brackets, Washers, U/LCA Components

• Powertrain-Pans, Gaskets, Covers, Brackets, Hardware

• Exhaust System components

MATERIALS

• Stainless Steel

• Aluminum

• Cold Rolled Steel

• Pre-coated Steel & Aluminum

• Electro-Galvanized

• Aluminized Steel

• Enameled Steels

• Bright, Brushed,or Mill Finish

• High Strength Low Alloy Material

SUPPORTING DEVELOPMENTS

• Complete Turnkey Project Management

• FKI can support Multiple Tool Package Developments from internal and external suppliers/customers

• Virtual Design Review

• PPAP- US Qualifications Available to Reduce Overseas Travel of Engineering Resources

• Welding, Test Fixtures, and Jig Development in Accredited Certified Facilities

• Simulation Validation and Reporting

• Laser Welded Fabrication

• Build to Print

• Weldments and Assemblies

• Utilizing Fully Licensed 3D CAD software

• Zeiss CMM with Calypso

• Hexagon Laser Scanning and PC Dimis inspection software

Hood Hinge Arm

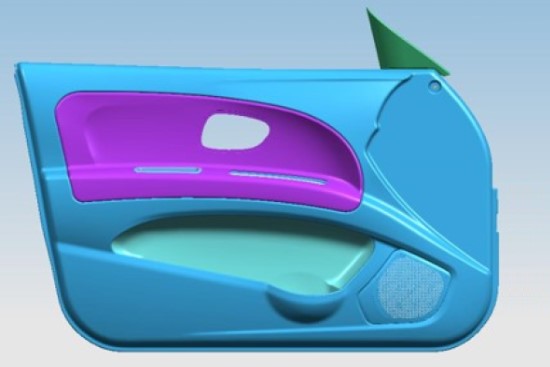

PLASTIC COMPONENTS

Polymers are utilized in almost all areas of the transportation industry due to their lightweight, durability, and cost-effectiveness. These materials have gained popularity over the years due to the development of high-performance structural polymers and innovations in manufacturing processes. These innovations allow the use of complex geometry, high wear resistance, and superior durability in all areas of the industry. These component material innovations are crucial for the transportation industry because they offer cost and performance advantages over other materials. Modern Polymers are lightweight, customizable, and can enhance the performance of many transportation products.

CAPABILITIES

• 400 plus injection molding machines worldwide

• Presses up to 1600 tons

• Sizes up to 85″ LCD Screens and 5KG shots possible

• Class A Cosmetic finishes

• Specializing in High Cosmetic finishes on larger components

• Pad Printing and Silk Screen Processing

• In-House Tooling fabrication & Maintenance

• World-class manufacturing from multiple locations, domestic and overseas

• All our injection molding facilities are certified (ISO 9001) 2015

ADDITIONAL FEATURES INCLUDE:

• Ultrasonic Welding, Assembly, Multi Shot Injection, Electroplating, Silk Screening and Pad Printing, Paint Wet and Dry Coating, and PVD Coating

MATERIALS

•All commonly Molded Polymers, including ABS, PE, PC, PET, PP, and Blends

• Structural Reinforced Polymers

• Proprietary Engineered Polymers

OEM PRODUCTS

Interior Trim, Seating, Lens, Brackets, Housings, Pans, Covers, Bezels, Door Handles, Electrical Connectors, Instrument Panels, Entertainment, as well as Steering, Suspension, Powertrain, Transmission, and clutch components

HOW IT’S MADE

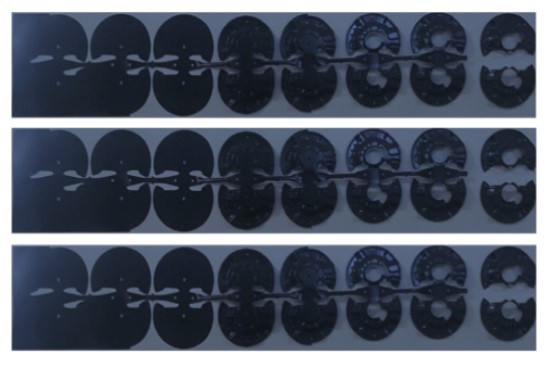

“When repeatability and large quantities are required, progressive metal stamping is usually the best alternative.”

FKI delivers standard and highly customized transportation products that fit our customers’ needs. We excel in engineering, prototyping, product development, and testing. With a focus on innovation and cost management, FKI has become a leading contract manufacturer to many companies.

For example, these brake shields are made with a progressive tool that produces two parts on each stroke of the press (left & right)

Auto Interior Parts Molded Plastic

Typically, injection molding produces parts much faster and is much more economical than either CNC machining or casting.

WATCH VIDEO

THE FKI ADVANTAGE

QUALITY &

CERTIFICATIONS

LEARN MORE

GLOBAL LOGISTICS &

PLANNING

LEARN MORE