EXPLORE THE CAPABILITIES

GET STARTED TODAYComputer Numerical Control, or CNC machining, is commonly used to manufacture metal or plastic parts, utilizing high-speed cutting machinery. At FKI, all our stamping and injection molding plants design, machine, and build the ultra-precision tools used in making our tooling and parts for all our tight tolerance, quality-critical applications.

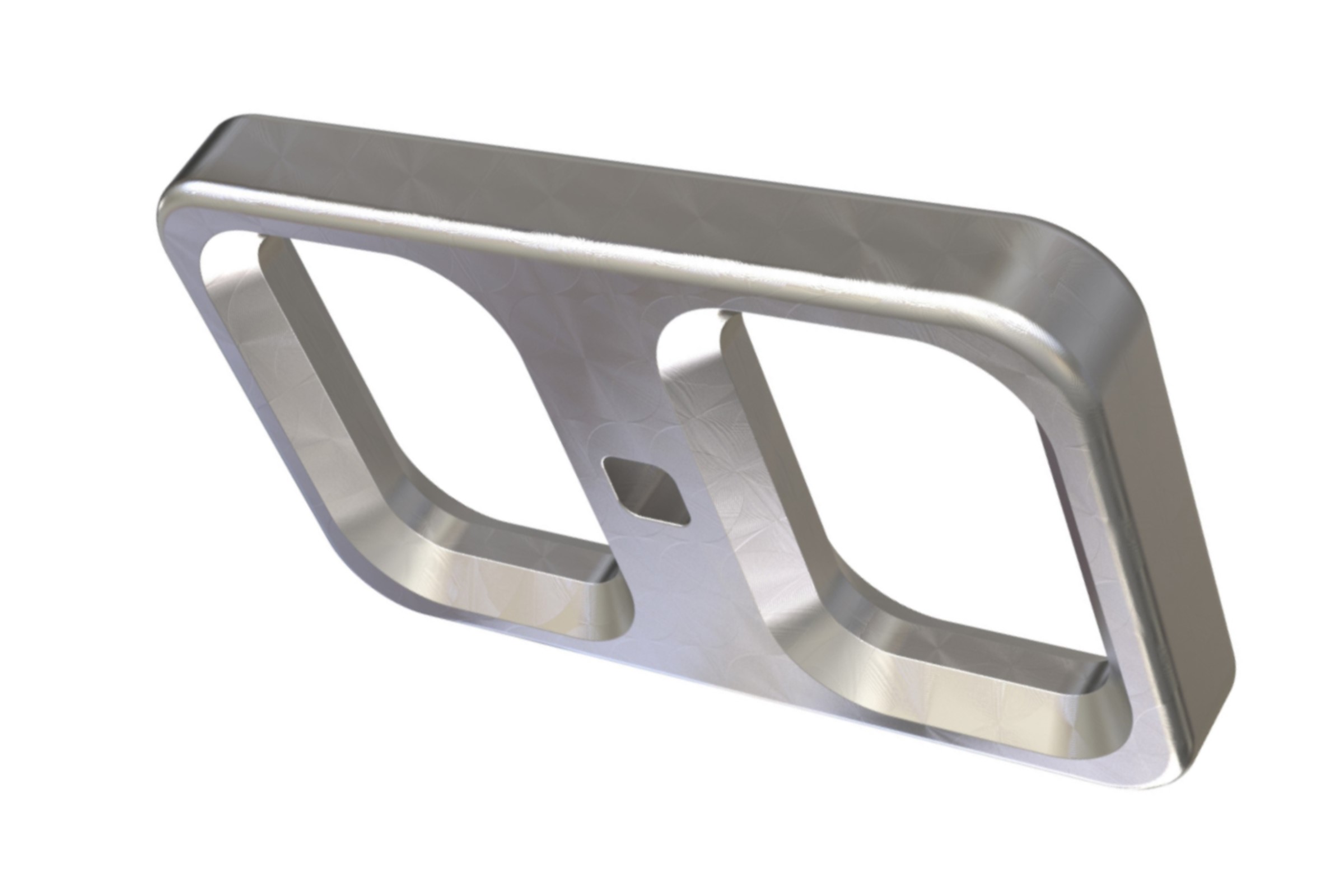

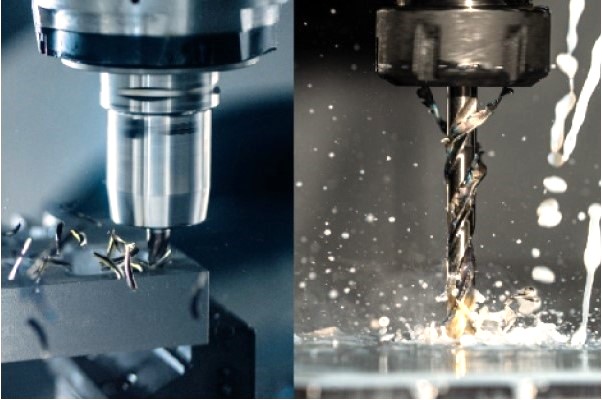

CNC MILLING

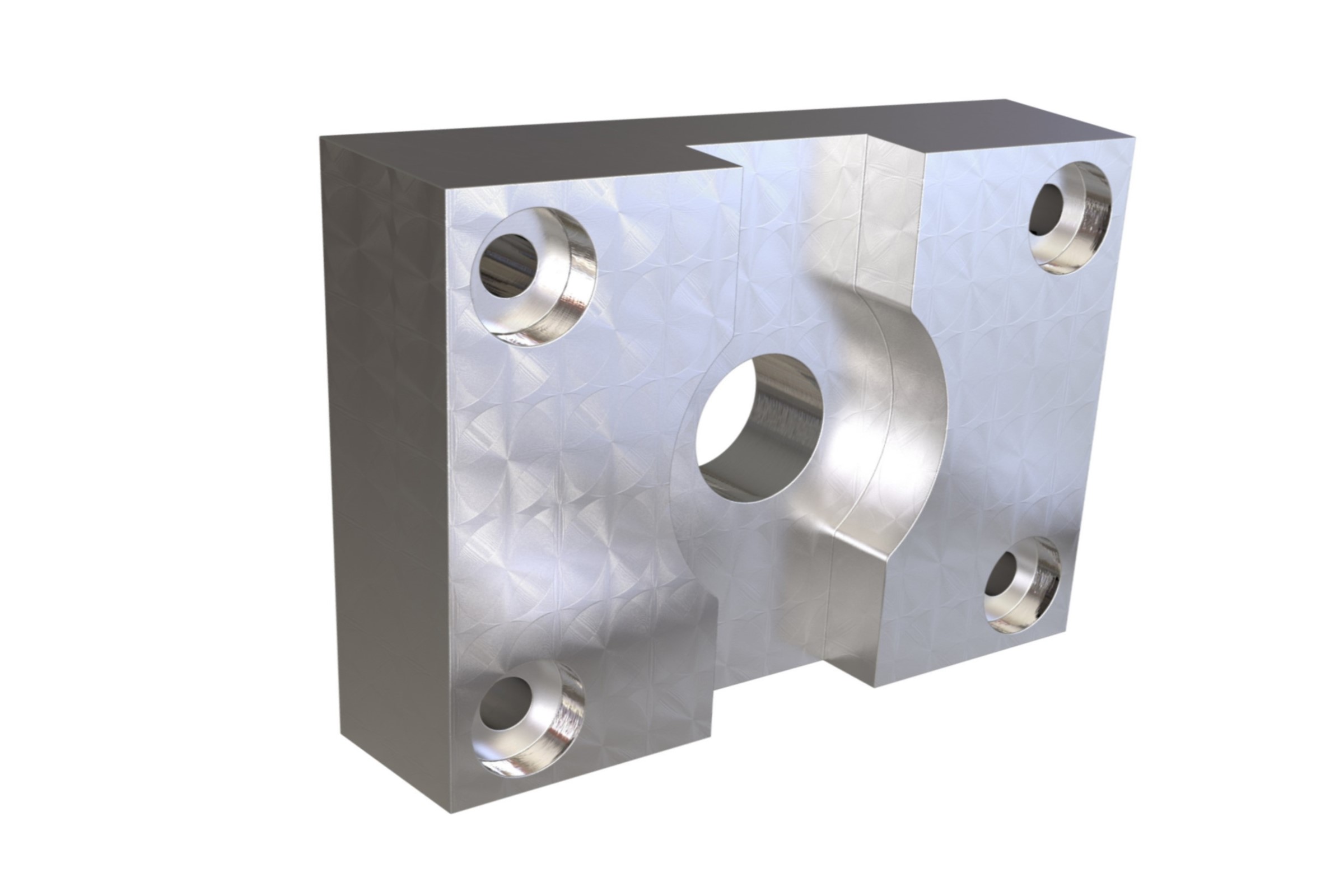

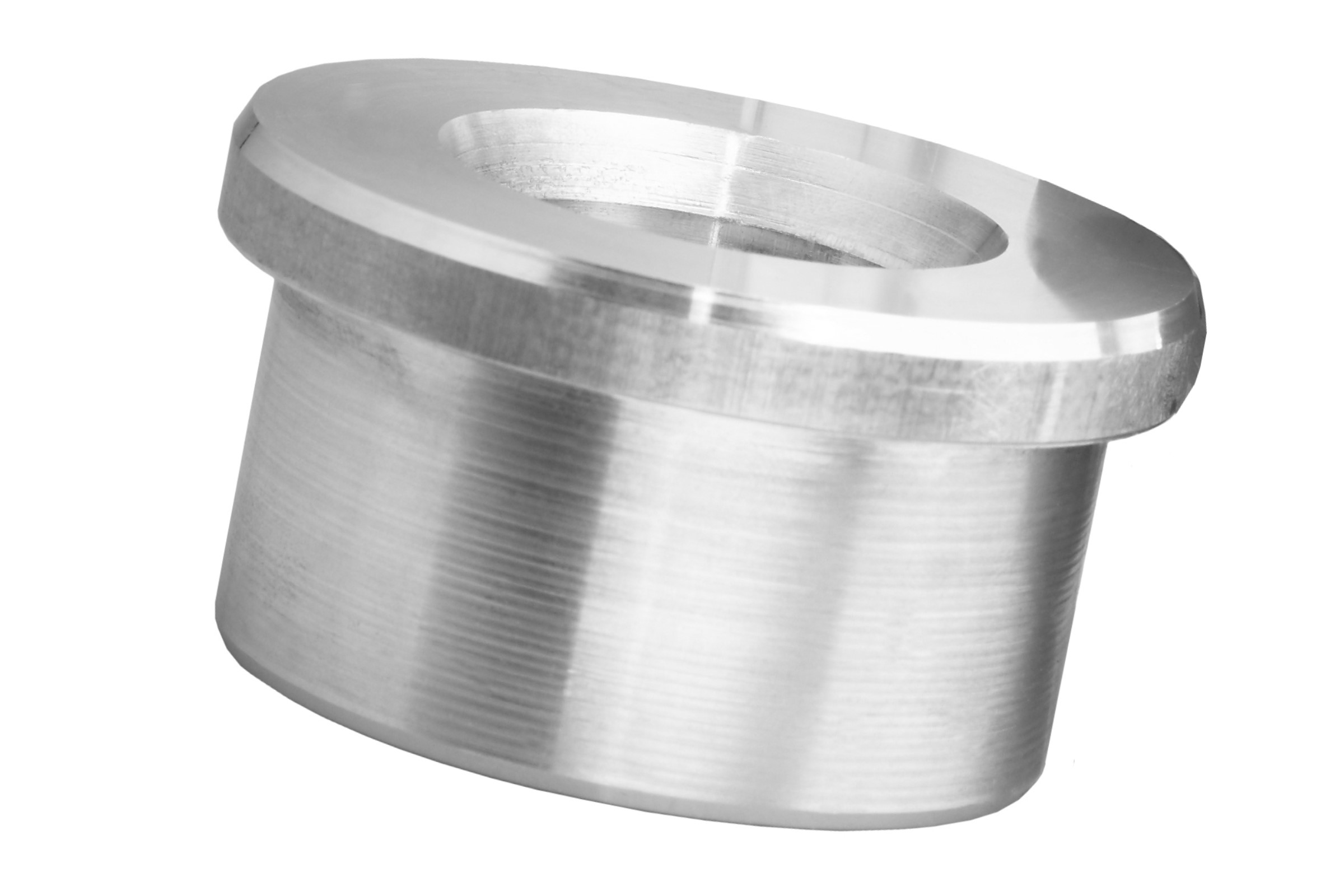

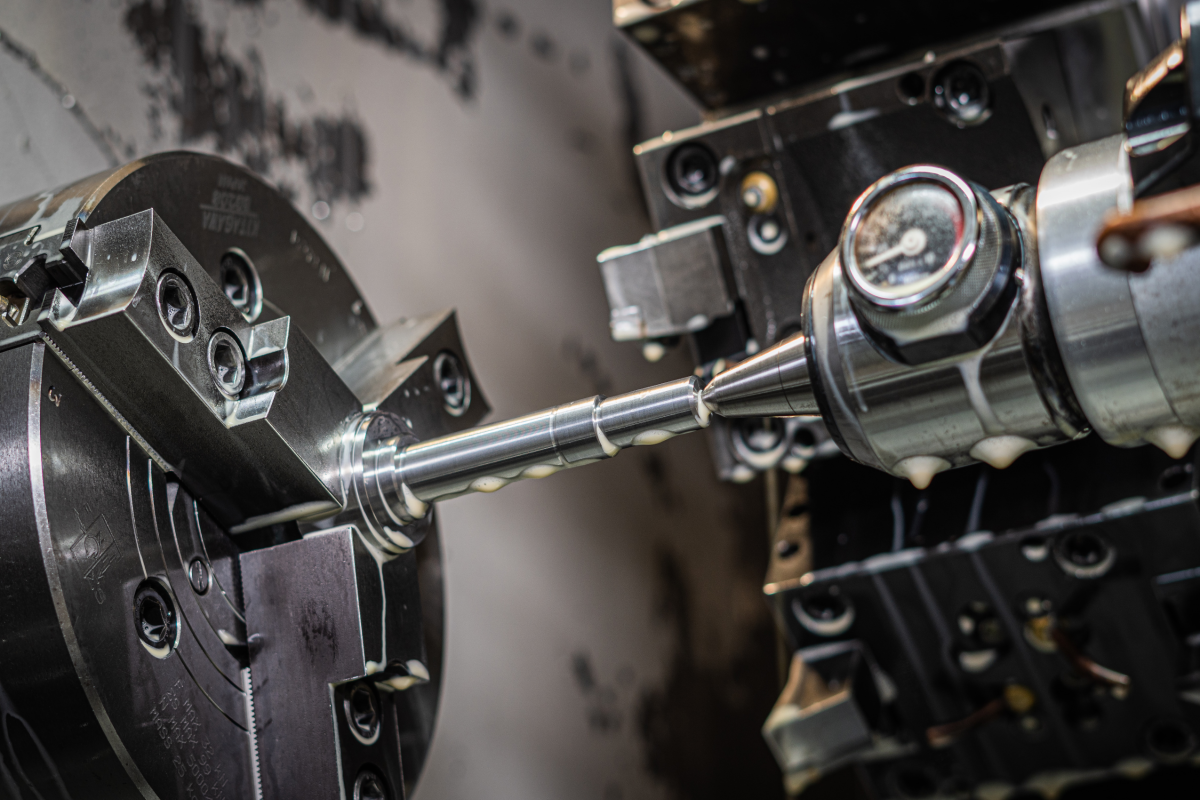

CNC TURNING

CNC PARTS

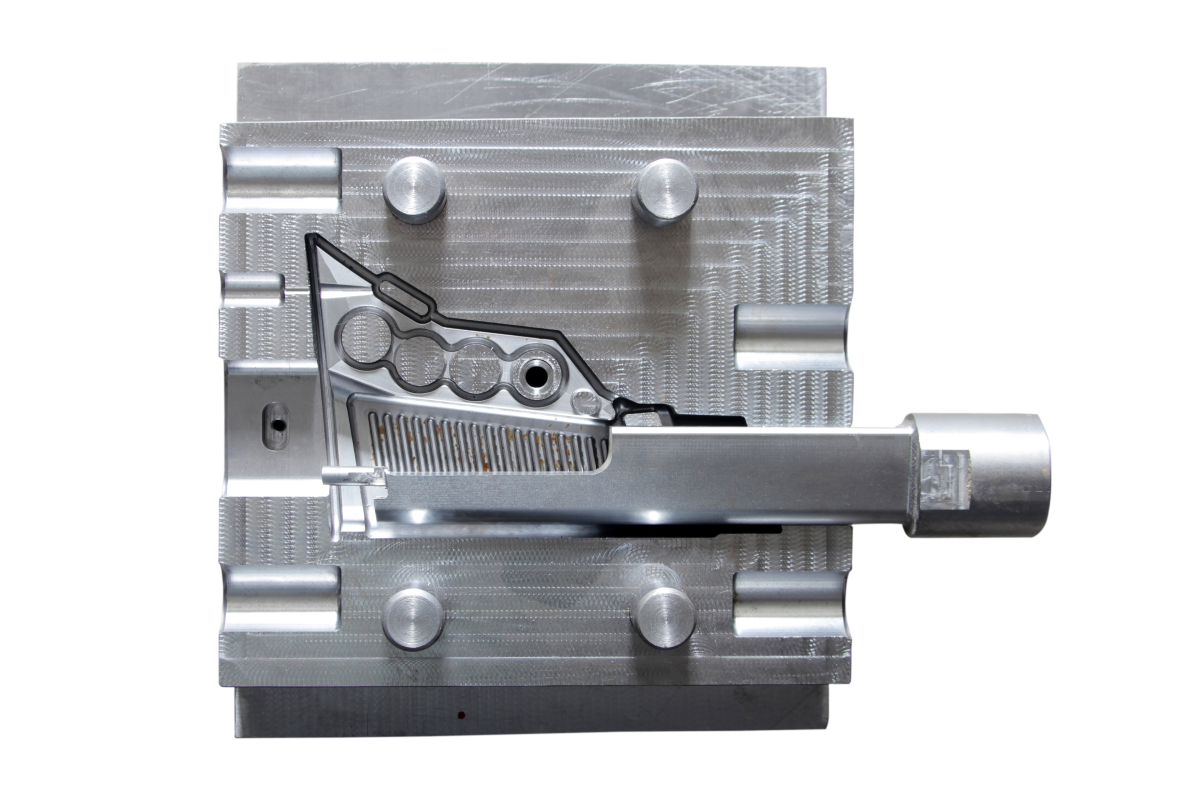

STAMPING TOOLING

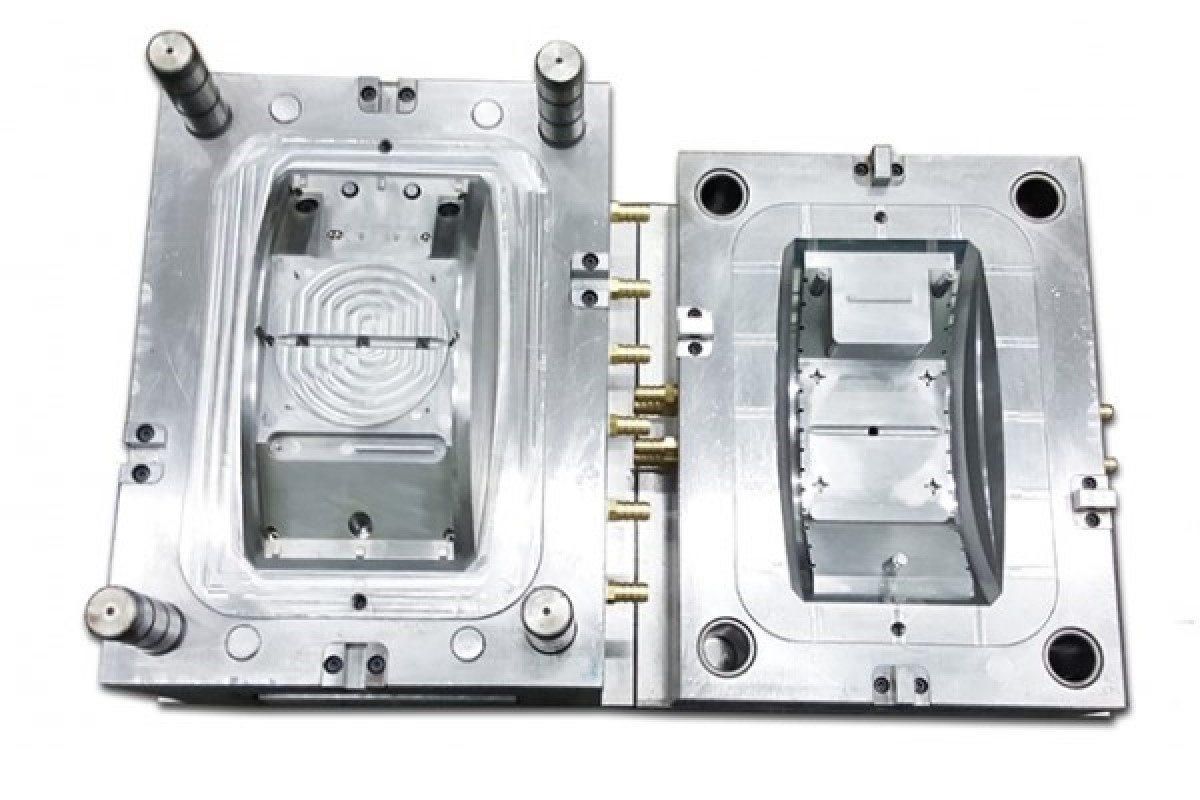

INJECTION MOLDING TOOLING

PROTOTYPES OR FULL PRODUCTION

FKI’s experienced machinists can meet or exceed the most demanding product requirements. Our in-house machining centers can accommodate metal, plastic, and composite materials and perform fabrication services, including Milling, Tapping, Threading, Boring, Drilling, and Turning processes.

Our best asset is our highly skilled machinists, many of whom have been in the industry for 30+ years. Their experience ensures less downtime and, ultimately, a high-quality product.

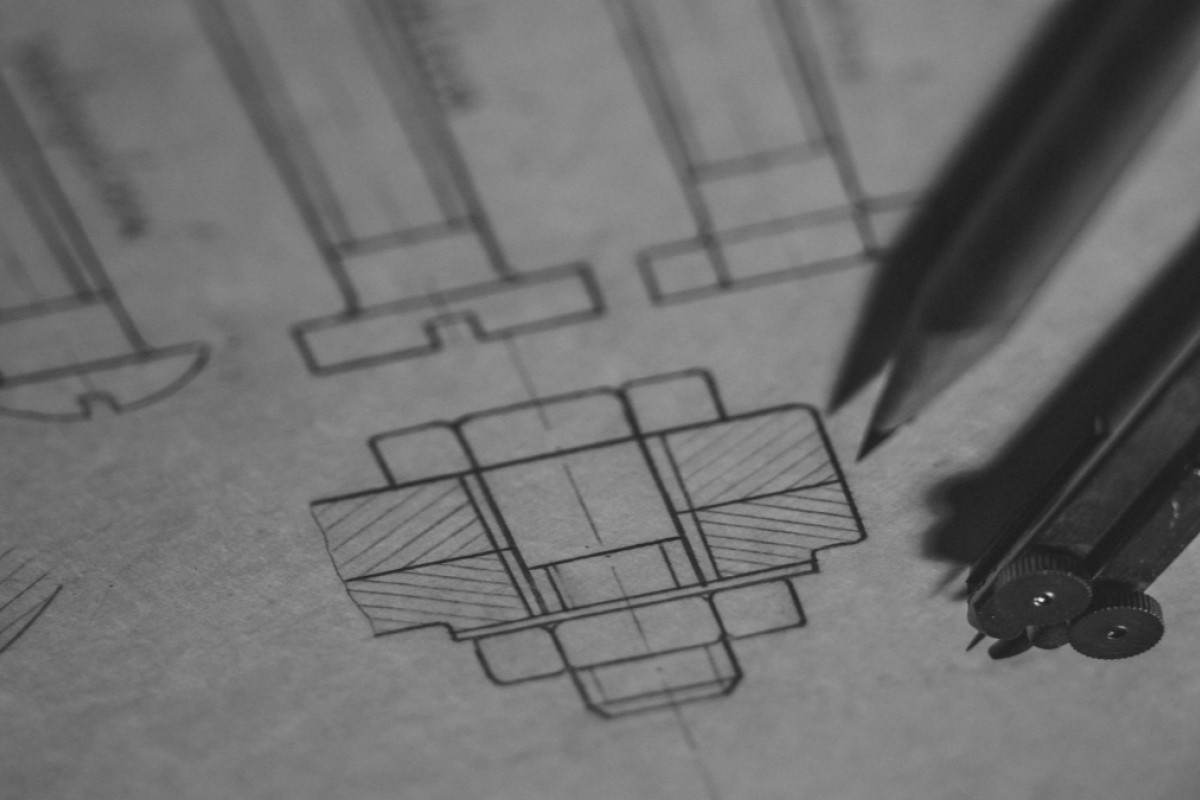

COMPLEX TOOLING AND DESIGNS

BENEFITS

• Short or long production runs

• Simple or Complex Designs

• Accuracy of parts

• Repeatability

• Rapid Prototyping

• US and Overseas Engineering and support

• Recyclable

ADDITIONAL SUPPORT EQUIPMENT

• Multi-Axis Milling Services

• CNC Turning up to 15 Inch Diameter and 36” Long

• Electro polishing & Plating

• Heat Treating

• Laser Welding

• Surface Grinding

• Centerless Grinding

SUPPORTING DEVELOPMENTS

• Complete Turnkey Project Management

• FKI can support Multiple Tool Package Developments from internal and external suppliers/customers

• Virtual Design Review

• PPAP- US Qualifications Available to Reduce Overseas Travel of Engineering Resources

• Welding, Test Fixture, and Jig Development in Accredited Certified Facilities

• Simulation Validation and Reporting

• Laser Welded Fabrication

• Build to Print

• Weldments and Assemblies

• Utilizing Fully Licensed 3D CAD software

• Zeiss CMM with Calypso

• Hexagon Laser Scanning and PC Dimis inspection software

CNC TURNING

A Subtractive process that typically creates round or cylindrical shapes by spinning the part at high speeds and removing material with the cutting tool.

CNC MILLING

A subtractive process in which the workpiece can be rotated or moved, and the tools can be stationary. In other cases, the tools move, and the workpiece is stationary. Another option is for both the tools and the workpiece to move.

THICK, THIN, BRIGHT, SATIN & MILL FINISH

We machine a variety of materials, mostly metals, but we also work with plastics and composites. We have years of experience working with difficult, exotic, and even volatile materials. FKI can help you select raw materials and source almost anything to meet your design and production requests.

METALS

• Stainless steel

• Aluminum

• Cold rolled steel

• Hot rolled steel

• Pre-coated steel and aluminum

• Electro- galvanized

• Aluminized Steel

• Enameled steels

• Brass & Copper

• Bright, Brushed, or Mill Finish

PLASTICS

• ABS – Acrylonitrile Butadiene Styrene

• PE – Polyethylene

• PC – Polycarbonates

• HIPPS – High Impact Polystyrene

• PET – Polystyrene

• PP – Polypropylene

• Nylon

• Proprietary Polymers

HOW IT’S MADE

Over the past 40 years, we have constantly invested in the best CNC machining technology worldwide.

Our engineering expertise has allowed FKI to become a superior CNC contract manufacturer for many industries and applications. However, the significant advantage is building and maintaining tooling in-house.

WATCH VIDEO

THE FKI ADVANTAGE

QUALITY &

CERTIFICATIONS

LEARN MORE

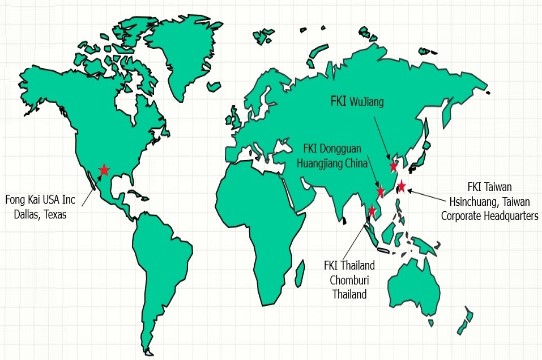

GLOBAL LOGISTICS &

PLANNING

LEARN MORE