EXPLORE THE CAPABILITIES

GET STARTED TODAYFKI is an experienced mechanical products manufacturer capable of providing complete product development services to our customers. We design products and provide real-world DFM benchmarking and the accountability of a company capable of manufacturing the products we create on time and within budget without compromising quality. Our talented design and engineering team is at the center of it all, dedicated to solving your manufacturing challenges and providing state-of-the-art results.

“We seamlessly provide the path from your idea to manufacturing.”

You can trust that FKI will engineer your stamping tool, mold, fixture, part, or product to work as intended. We make products for Fortune 1000 companies in the following industries:

DESIGN & ENGINEERING SERVICES

FKI provides world-class engineering services that are leveraged by global manufacturing capabilities. A common challenge for design and engineering firms is developing a capable product while maintaining cost goals without compromising quality.

SUPPORTING DEVELOPMENTS

• Complete Turnkey Project Management

• FKI can handle large Tooling Packages from multiple suppliers/customers

• Virtual Design Review

• PPAP- US Qualifications Available to Reduce Overseas Travel of Engineering Resources

• Test Fixture and Jig Development in Accredited Certified Facilities

• Simulation Validation and Reporting

• Laser Welded Fabrication

• Build to Print

• Weldments and Assemblies

• 3D CAD software is preferred file extensions: PRT, IGES, STEP, DXF or DWG, SLDPRT, SAT, and STL

PRODUCTS WE SUPPORT

• Computing Products

• Mechanical Engineering and Development

• PC, Servers & Workstations

• Thin Client Chassis

• Network Devices

• LCD TV Enclosures (Complete Mechanical Enclosure Design and Development)

• Consumer Electronics

• Appliance Products

• Industrial Products

• Automotive & Transportation Products

• HVAC Products

ENGINEERING SOFTWARE TOOLS

• PTC Pro Engineer

• Siemens / Unigraphics PLM / NX

• SolidWorks

• Autodesk Inventor / Autocad and Fuzion 360

• Autoform Dynaform Simulation Services Available

BIG TONNAGE

The perfect combination utilizing a 60″ x 132″ stamping press and 5/8″ steel plates. Each part weighs about 150 lbs, and measures 21″ x 45”. Parts are formed in a 600-ton stamping press to strict tolerances. Our skilled craftsman will perform a quality check on every part in a check fixture to ensure conformity. Let FKI show you how we can solve your next “BIG” project.

HOW IT’S MADE

THE PROCESS

• Large sheets of steel are sourced

• Individual parts are laser cut to size

• Parts are loaded into stamping press & formed

• Individual parts are removed from press

• Parts are quality checked in a fixture.

• Parts are stacked & banded to skids

THE FKI ADVANTAGE

QUALITY &

CERTIFICATIONS

LEARN MORE

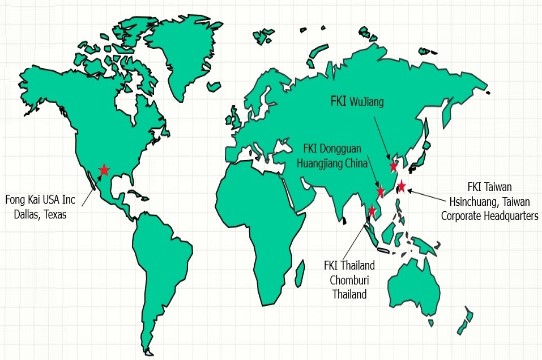

GLOBAL LOGISTICS &

PLANNING

LEARN MORE