EXPLORE THE CAPABILITIES

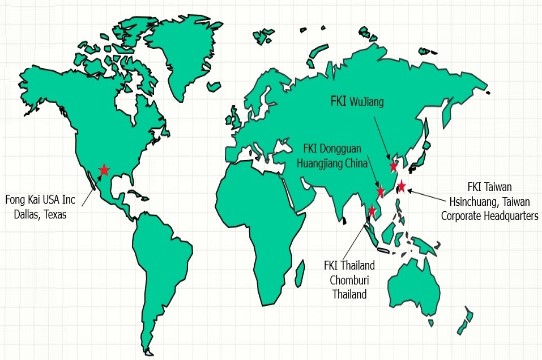

GET STARTED TODAYFKI is a global manufacturer that can support customers from concept to production. We have engineering expertise and experience developing and manufacturing various computing products for many easily recognized brands. We are the manufacturer of choice for many successful Fortune 500 companies. FKI provides best-in-class OEM /ODM full-service computer builds. We offer complete electro-mechanical, in-house development, prototyping, engineering, and testing services. Specialize in computer workstations, desktop, and server barebone chassis; Trust FKI for your complete supply chain management and turnkey solutions for all your computing programs, including:

PCBA & ENCLOSURES

DISPLAY & KEYBOARDS

ELECTRICAL ENCLOSURES

SERVER CHASSIS

PRINTERS & COPIERS

WORKSTATION & BOX BUILDS

COMPLETE ASSEMBLIES

CONCEPT TO PRODUCTION

FKI has the expertise to develop, design, and manufacture products for customers in the consumer electronics and computing product spaces. As a global industrial supplier, we can support customers from concept to global production. Our services, which include program management, design support, engineering, and design for manufacturing (DFM), are designed to cater to a wide range of needs. We offer world-class manufacturing from multiple locations depending on volume or labor content, whether it’s production samples, prototypes, or mass production. Our USA facility can provide engineering services, final assembly, testing, warehousing, and inventory management. Simple or complex, small or large quantities, FKI is here to serve. Our production can even accommodate seasonal or peak demand variations.

QUALITY

All our facilities are ISO 9001:2015 certified while meeting or exceeding ISO 9001-14001 and OHSAS 1800 certified quality systems. In addition, FKI is compliant and maintains UL, CSA, NSF, and CE registration. We can comply with and document material certifications, ITAR, and hardware traceability standards, and we conform to the following:

• IPC A-610 – standard manufacturability of electronic assemblies

• IPC/WHMA A-620 standards – cable and wire harness assembly

• IPC A-630 – standards for manufacture

• IPC A-630 – Standards for inspection

• IPC A-630 – Standards for testing of Electronic Enclosures,

RoHS compliant

OEM – COMPUTER PRODUCTS

• Pointing Devices

• Displays

• Keyboards

• Printers

• Scanners

• Copiers

• Workstations

• PCB assemblies

• Set Top Boxes

• Satellite Tuner Chassis

• Cable Modem Enclosures

• DSL Modem and Router Enclosures

• Router and Switch Housings

• Enclosures for the Healthcare Industry

• LCD Display

• Switch and Sensors Assemblies

PRINTERS, COPIERS, SCANNERS & COMPONENTS

FKI provides the perfect mix of metal and plastic components wrapped into a complete build and integration. We manufacture components used in scanners, copiers, inkjet printers, laser printers, 3D printers, and LED printers.

DISPLAYS

Our OEM/ODM Display products are produced using state-of-the-art equipment. Automated processes and robotics reduce manufacturing costs and increase quality. In addition, we manufacture metal brackets, braces, and many internal components.

PRODUCTS INCLUDE

• Display Fronts

• Display Backs

• LED Shades

• Liquid Crystal Components

• Tablet

• Touchscreen

POINTING DEVICES, KEYBOARDS, AND EARPHONES

From concept to finished product. Once a design has been finalized, our molding machines make the plastic components, and we combine the metal. Our competitive advantage is utilizing in-house capabilities to decorate, package, and give our customers a retail-ready product.

OUR PRODUCTS

• Keycaps

• Case

• PCB

• Power Cables

• Stabilizers

• Switches

• Wires

• Cylinder

• Diaphragm

• Infrared Mouse

• Optical Mouse

• Trackball

• Touchpad

• Joystick

• Pens

ASSEMBLY

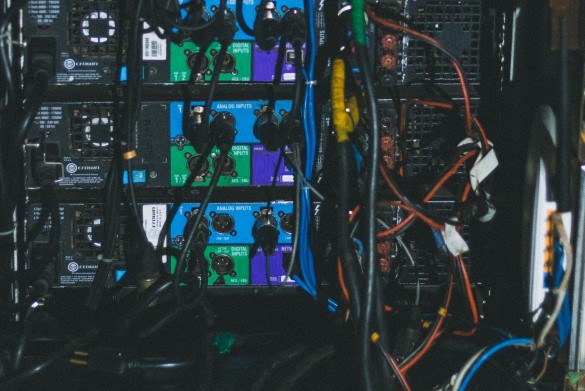

Our typical assemblies have a combination of mechanical and electronic components housed within a metal or plastic enclosure. Enclosure, Power supply, PCBA, Electronic Components, Connectors, Wire Harness, Mechanical components, Thermal Management, and Shielding EMI/RFI. Processes utilized include:

• Moving Assembly lines

• Bench Assembly

• Focused Cell Assembly

• Offshore or USA build

Our Team can help you decide the best method suited for your product.

COMPONENTS / ELECTRONICS / WIRE HARNESS

We develop and manufacture connection and termination solutions for various applications and markets. Our customers rely on FKI to help navigate and overcome obstacles with interconnecting devices. The FKI team can help get your product to market quickly by utilizing best practices, including DFM, DFX, and NPI. All components & sub-assemblies can be incorporated into the build and can include, but not limited to:

• Wire Harness

• Cable Assemblies

• PCBA

• PLC

• Power Supply

• DIN Rails

• Relays

• Pneumatics

SUPPORTING DEVELOPMENTS

• Complete Turnkey Project Management

• FKI can support Multiple Tool Package Developments from internal and external suppliers/customers

• Virtual Design Review

• PPAP- US Qualifications Available to Reduce Overseas Travel of Engineering Resources

• Welding, Test Fixture, and Jig Development in Accredited Certified Facilities

• Simulation Validation and Reporting

• Laser Welded Fabrication

• Build to Print

• Weldments and Assemblies

• Utilizing Fully Licensed 3D CAD software

• Zeiss CMM with Calypso

• Hexagon Laser Scanning and PC Dimis inspection software

PRODUCT DEVELOPMENT PROCESS

• Compliance Validation and Testing

• Emission Compliance Engineering and Design

• Thermal Management and Mitigation Strategies

• REACH, RoHS, and Blue Angel Development Standards

• PCR and Recyclability Content

• Shock and Vibration Testing and Compliance Validation

• Mechanical Development

• Project Timeline and BOM management

SECONDARY PROCESS SUPPORT

• Sourcing and development of Cables and Harness

• Thermal Management Products

• Fans, Blowers, Heat Sinks, Coolers

• Power Supply Development and Sourcing

• Assembly and Integration of Plastic and Metal Components

• Electro-Mechanical Components

HOW IT’S MADE

MOVING & STATIONARY ASSEMBLY LINES

FKI utilizes the latest technology in our moving lines.

Our team of engineers can help determine the best production method, considering quantity, complexity, flexibility, and costs.

THE FKI ADVANTAGE

QUALITY &

CERTIFICATIONS

LEARN MORE

GLOBAL LOGISTICS &

PLANNING

LEARN MORE