EXPLORE THE CAPABILITIES

GET STARTED TODAYOur boxes and assemblies can include all the mechanical and electrical components, including the final assembly and worldwide logistics. FKI provides complete OEM /ODM full-service mechanical and electrical box builds. Our services reduce costs, improve reliability, performance, quality, productivity, and minimize risk. Trust FKI for your complete supply chain management and turnkey solutions for your Box Build, including but not limited to:

EVERYTHING INSIDE AND MORE

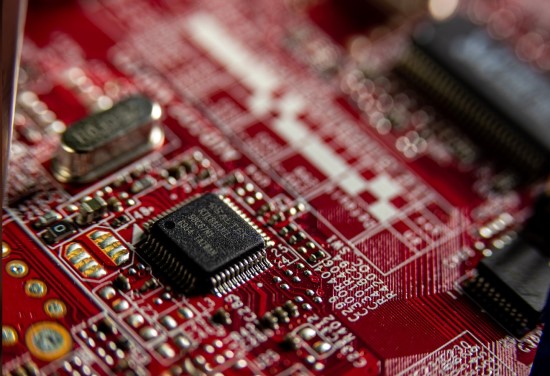

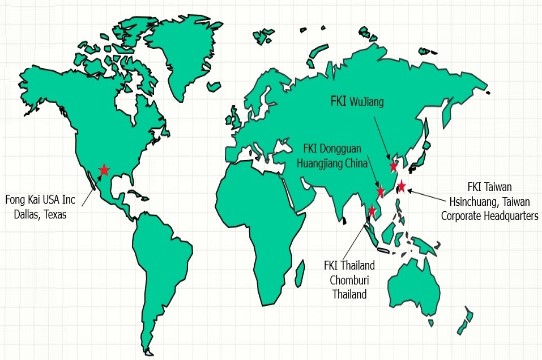

Our boxes can perform simple or complex tasks, such as power generation, switching, controls, and incorporating various integrated circuits. We can handle all the procurement, design, engineering, prototyping, testing, and final production. We offer world-class manufacturing from several locations overseas, depending on volume or labor content. Our US facility can provide engineering services, final assembly, testing, warehousing, and inventory management.

FROM CONCEPT TO PRODUCTION

QUALITY

Our ISO 9001:2015 certification ensures we establish, implement, maintain, and continually improve our QMS. We aim to meet our customers’ expectations and demonstrate our commitment to quality. Our facilities meet or exceed ISO 900114001. We comply with UL, CSA, NSF, and CE standards. Our industry certifications include the following:

• IPC A-610 standards – acceptability of electronic assemblies

• IPC/WHMA A-620 standards – cable and wire harness assembly

• IPC A-630 – standards for manufacture

• IPC A-630 – Standards for inspection

• IPC A-630 – Standards for testing of Electronic Enclosures,

• RoHS compliant

WE PROVIDE THE FOLLOWING VALUE

FLEXIBILITY

Box builds are all different, and each one has challenges. We can modify and adapt to an engineering change, assembly process improvement, or component change. An effective box build will always have challenges, but our team is excellent at adapting to our customers’ needs.

SCALABILITY

FKI has the worldwide resources to scale your box build almost effortlessly. The marketplace pressures are constantly changing, and our operations are geared to handle any fluctuations in demand. We aim to develop and scale our operations seamlessly and provide our customers with the required volume of products when needed.

CUSTOMIZATION

You are never alone, and our staff of technicians, engineers, and dedicated professionals can handle your unique challenges and specifications. We can help with all design and manufacturing aspects, just like we have done for many major brands worldwide.

QUALITY CONTROL

Our products stand the test of time and must pass the most rigorous testing assembly inspection every time. All our facilities are ISO certified (ISO 9001) 2015

OUR SUPPORTING PRODUCTS

OEM – PC COMPUTER CHASSIS

• Rack Mount Server Chassis

• Workstation Chassis

• Thin Client Chassis

• DVD Chassis

• Satellite Tuner Chassis

• Cable Modem Enclosures

• DSL Modem and Router Enclosures

• Battery Assemblies

• Switch and Sensors Assemblies

• Circuit Breaker boxes

• Router and Switch Housings

ELECTRONICS & MECHANICAL PRODUCTS

• Flat Screen TV Assemblies

• Set Top Boxes

• Cable Boxes

• Transformers

• Camera Housings

• Enclosures for the Healthcare Industry

• LCD Display

• Displays

• Pointing Devices

• Keyboards

• Optio-Electronics

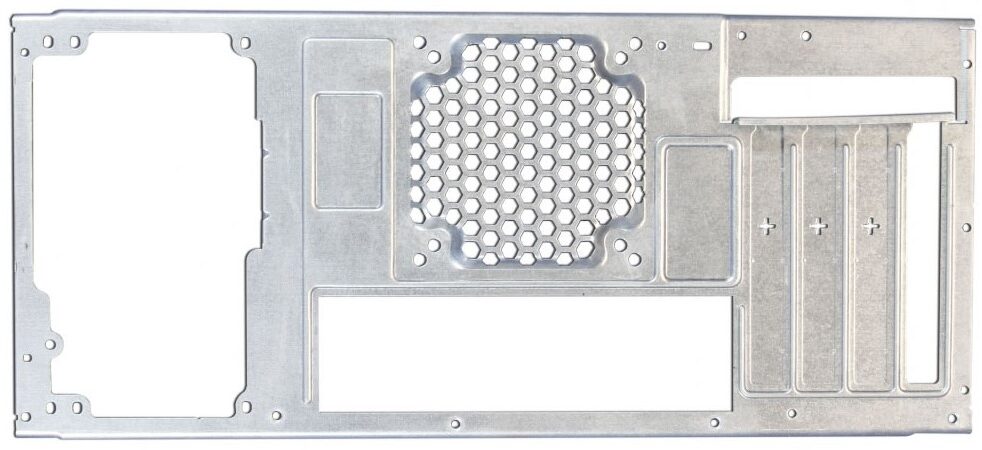

METAL COMPONENTS

Metal is formed into simple or complex shapes using stamping, shearing, punching, sawing, drilling, grinding, taping, bending, CNC turning, CNC machining, laser cutting, and welding, and can include hardware. Components can be painted, plated, anodized, and powder-coated before assembly. We can provide individual components or a complete box build. Metals are widely used in the “Build a box” industry for their strength, durability, and beauty, and they make the structure of the boxes, brackets, and supports. It is commonly used to support other components and keep everything aligned in the box. We will help you produce a cost-effective, high-quality box or component that meets or exceeds your needs.

CAPABILITIES

• Over 620 metal stamping presses worldwide.

• 60 Ton up to 2000 Ton

• Presses Beds up to 72″ x 177″

• Progressive & Transfer Stamping

• Class A Cosmetic products

• Specializing in Deep Draw stamping of larger components

• In-House Tooling Build & Maintenance

• US Qualifications available to reduce overseas travel of Engineering Resources

• World-class manufacturing from multiple locations overseas or from our US facility

• Our stamping facilities are certified (ISO 9001) 2015 or better.

ADDITIONAL SERVICES INCLUDE:

Assembly, Wet and Dry Coatings, Printing, Tapping, Top Coating, Deburring, Plating, and PVD Coating

MATERIALS

• Stainless Steel

• Aluminum

• Cold Rolled Steel

• Pre-coated Steel & Aluminum

• Electro-Galvanized

• Aluminized Steel

• Enameled Steels

• Bright, Brushed, or Mill Finish

• High Strength Low Alloy Material

OEM PRODUCTS

Boxes, Brackets, and Supports mainly support other components and keep things aligned in the box.

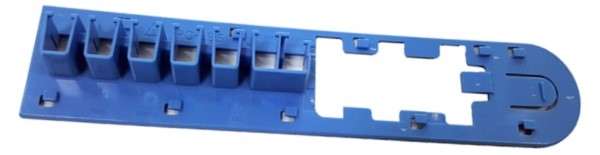

PLASTIC COMPONENTS

Plastic injection molded components are used extensively in the Build-A-Box industry to improve their performance, durability, and visual appeal. The use of plastics in assemblies is dependent on the application. These plastic components are crucial for the Build-A-Box industry because they offer many advantages over other materials. Plastics are lightweight, customizable, and enhance the performance of the build. Plastics can be cost-effective for customer design changes and ongoing flexibility. Plastic is both cost-effective and flexible for use inside and outside a Box.

CAPABILITIES

• 400 plus injection molding machines worldwide

• Presses up to 1600 tons

• Sizes up to 85″ LCD Screens and 5KG shots possible

• Class A Cosmetic finishes

• Specializing in High Cosmetic finishes on larger components

• Pad Printing and Silk Screen Processing

• In-House Tooling fabrication & Maintenance

• Overseas Qualifications available

• World-class manufacturing from multiple locations overseas

• All our injection molding facilities are certified (ISO 9001) 2015

ADDITIONAL FEATURES INCLUDE:

Paint Wet and Dry application, Multi Material Multi Shot, Plating and CNC Machining

MATERIALS

• ABS – Acrylonitrile Butadiene Styrene

• PE – Polyethylene

• PC – Polycarbonates

• PET – Polystyrene

• PP – Polypropylene

• HIPPS – High Impact Polystyrene

• Nylon

• Proprietary Polymers

OEM PRODUCTS

• Boxes

• Brackets

• Supports

• Trays

• Clips

• Covers

• Bezel

• Assortment of plastic components

ASSEMBLY

• Press-to-Fit

• Screws

• Snap-Fit

• Plastic Welding

• Adhesive

SUPPORTING DEVELOPMENTS

• Complete Turnkey Project Management

• Sourcing and development of Cables and Harness

• Thermal Management Products

• Fans, Blowers, Heat Sinks, Coolers

• Power Supply Development and Sourcing

• Assembly and Integration of Plastic and Metal Components

• Electro-Mechanical Components

• Build to Print

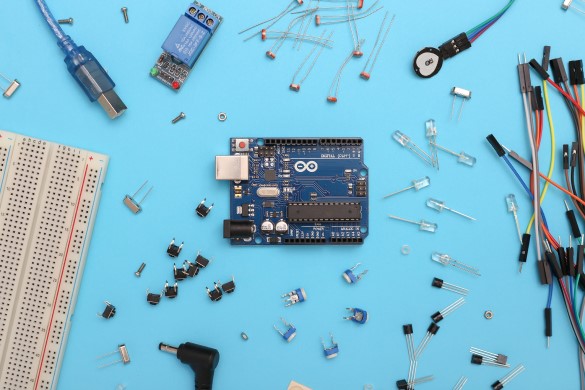

COMPONENTS / ELECTRONICS / WIRE HARNESS

We develop and manufacture solutions for an assortment of applications and industries. Our customers rely on FKI to help navigate and overcome obstacles with today’s challenging interconnection of devices. The FKI team can help get your product to market quickly by utilizing best practices, including DFM, DFX, and NPI. All components & sub-assemblies can be incorporated into the build:

• Wire Harness

• Cable Assemblies

• PCB

• PLC

• Power Supply

• DIN Rails

• Relays

• Pneumatics

ASSEMBLY

Our Team can help you decide the best method suited for your product. From simple to elaborate, we deliver exceptional products at an affordable price. A Variety of assembly methods are utilized, including:

• Moving Assembly lines

• Bench Assembly

• Focused Cell Assembly

• Offshore or USA build

HOW IS IT MADE

MOVING & STATIONARY ASSEMBLY LINES

Moving lines are used when parts are added as a semi-finished assembly moves from station to station, and parts are added in sequence until the final assembly is produced.

Stationary lines are used when components are assembled at a fixed location, and the workers move from one station to the next to complete the assembly.

Our team of engineers can help determine the best method of production taking into consideration, quantity, complexity, flexibility, and costs.

THE FKI ADVANTAGE

QUALITY &

CERTIFICATIONS

LEARN MORE

GLOBAL LOGISTICS &

PLANNING

LEARN MORE