EXPLORE THE CAPABILITIES

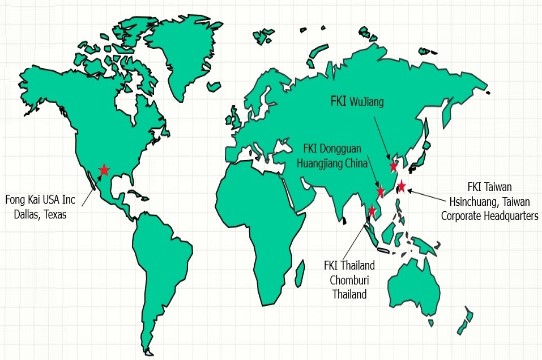

GET STARTED TODAYWith our extensive engineering expertise and global manufacturing experience, FKI is a fully integrated supplier that can support customers from concept to production. We are the manufacturer of choice for many successful Fortune 1000 brands, providing best-in-class OEM /ODM full-service consumer electronics builds. Trust FKI for your complete supply chain management and turnkey manufacturing for all your Consumer Electronics.

DISPLAYS & KEYBOARDS

COPPIER & PRINTER

PCBA & ENCLOSURES

WIRE HARNESS & CABLES

POWER & THERMAL MGT

ELECTRONIC

PRODUCTS

OEM/ODM CONSUMER PRODUCTS

FKI designs, develops, and manufactures products for OEM/ODM customers. It is well-positioned to support mechanical component development programs. We can manage procurement, design, engineering, prototype fabrication, testing, and final production. Depending on volume or labor content, we offer world-class manufacturing from multiple locations overseas. Our US facility can provide engineering services, final assembly, testing, warehousing, and inventory management.

OEM – ELECTRONICS & MECHANICAL PRODUCTS

• Pointing Devices

• Displays

• Keyboards

• Earphones

• Small Appliance

• Flat Screen TV Assemblies and components

• Set Top Boxes

• Consoles

• Camera Housings

• Networking, Router and Switch Enclosures

• Products for the Healthcare Industry

• LCD Displays

• Circuit Breaker Enclosures

• Battery Assemblies

• Switch and Sensors Assemblies

QUALITY

CMM – 3D measurement of part

All our facilities are ISO 9001:2015 certified while meeting or exceeding ISO 900114001; FKI is also familiar with compliance and maintains UL, CSA, NSF, and CE standards. We can comply with and document material certifications.

• IPC A-610 standards – acceptability of electronic assemblies

• IPC/WHMA A-620 standards – cable and wire harness assembly

• IPC A-630 – standards for manufacture

• IPC A-630 – Standards for inspection

• IPC A-630 – Standards for testing of Electronic Enclosures

• RoHS compliant

In addition, we manufacture a variety of lead-free electronic products.

OEM – PRINTERS, COPIER, SCANNER & COMPONENTS

FKI provides the perfect mix of metal and plastic components wrapped into a complete build and integration. Our components are used in inkjet printers, laser printers, 3D printers, and LED printers.

COMPONENTS INCLUDE:

• Chassis

• Gears

• Lenses

• Cases

• Covers

• Lids

• Feeder Tray

• Toner Caddy

• Cartridge Holders

• Sheet Feeder Tray

• Tray Extension

• Connectors

• Edge Guides

• Cartridge Cover

• Control Buttons

• Toner Cartridges

• Rollers and Gears.

DISPLAYS AND TV’S

Our OEM/ODM Display products are manufactured with hydraulic, electric, or hybrid plastic injection molding machines. Servo robotics, throughout the highly automated process, helps reduce manufacturing costs and increase quality. In addition, we manufacture metal brackets, braces, and many internal components.

COMPONENTS INCLUDE:

• Front Panels

• Back Panels

• Decorative Trim and Footings

• LED Shades

• Liquid Crystal Components

• Tablet

• Touchscreen

POINTING DEVICES, KEYBOARDS, AND EARPHONES

From concept to finished product. Once a design has been finalized, our molding machines make the plastic components, and we combine the metal. Our competitive advantage is utilizing in-house capabilities to decorate, package, and give our customers a retail-ready product.

COMPONENTS INCLUDE:

• Keycaps • Cylinder

• Case • Diaphragm

• PCB • Infrared Mouse

• Power Cables • Optical Mouse

• Stabilizers • Trackball

• Switches • Touchpad

• Wires • Joystick, and Pen

ASSEMBLY

Our Projects include mechanical and electronic components housed within a metal or plastic enclosure. These components are assembled to meet our customers’ specifications. Projects include Enclosures, Power supplies, PCBAs, Electronic Components, Connectors, Wire Harnesses, Mechanical components, Thermal Management, and Shielding EMI/RFI.

A Variety of assembly methods are utilized including:

• Moving Assembly lines

• Bench Assembly

• Focused Cell Assembly

• Offshore and Domestic build

Our Team can help you decide the best method suited for your product.

Television Assembly Line – Clean Room

COMPONENTS / ELECTRONICS / WIRE HARNESS

We develop and manufacture solutions for an assortment of applications and industries. Our customers rely on FKI to help navigate and overcome obstacles with today’s challenging interconnection of devices. The FKI team can help get your product to market quickly by utilizing best practices, including DFM, DFX, and NPI. All components & sub-assemblies can be incorporated into the build:

HOW IT’S MADE

MOVING & STATIONARY ASSEMBLY LINES

Moving lines are used when parts are added as a semi-finished assembly moves from station to station, and parts are added in sequence until the final assembly is produced.

Stationary lines are used when components are assembled at a fixed location, and the workers move from one station to the next to complete the assembly.

Our team of engineers can help determine the best production method, taking into consideration quantity, complexity, flexibility, and costs.

THE FKI ADVANTAGE

QUALITY &

CERTIFICATIONS

LEARN MORE

GLOBAL LOGISTICS &

PLANNING

LEARN MORE