EXPLORE THE CAPABILITIES

GET STARTED TODAYAT FKI, OUR MOST IMPORTANT PRODUCT IS YOUR PRODUCT

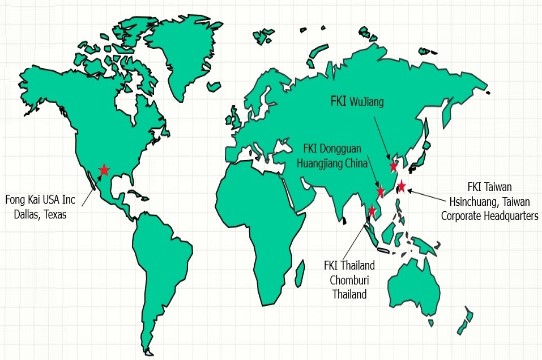

FKI is a contract manufacturing company, we are a dedicated private label or white label contract manufacturer for our partner companies. As a global manufacturing company, we provide seamless shipping and deliver custom products made from various materials, colors, and sizes to our ever-expanding customers as quickly as possible. Our commitment to order accuracy and customer service will help you get precisely what you need when you need it. You can count on us to help you get the job done right.

DISPLAY & KEYBOARDS

PBCA & ENCLOSURES

WORKSTATION & BOX BUILDS

SERVER CHASSIS

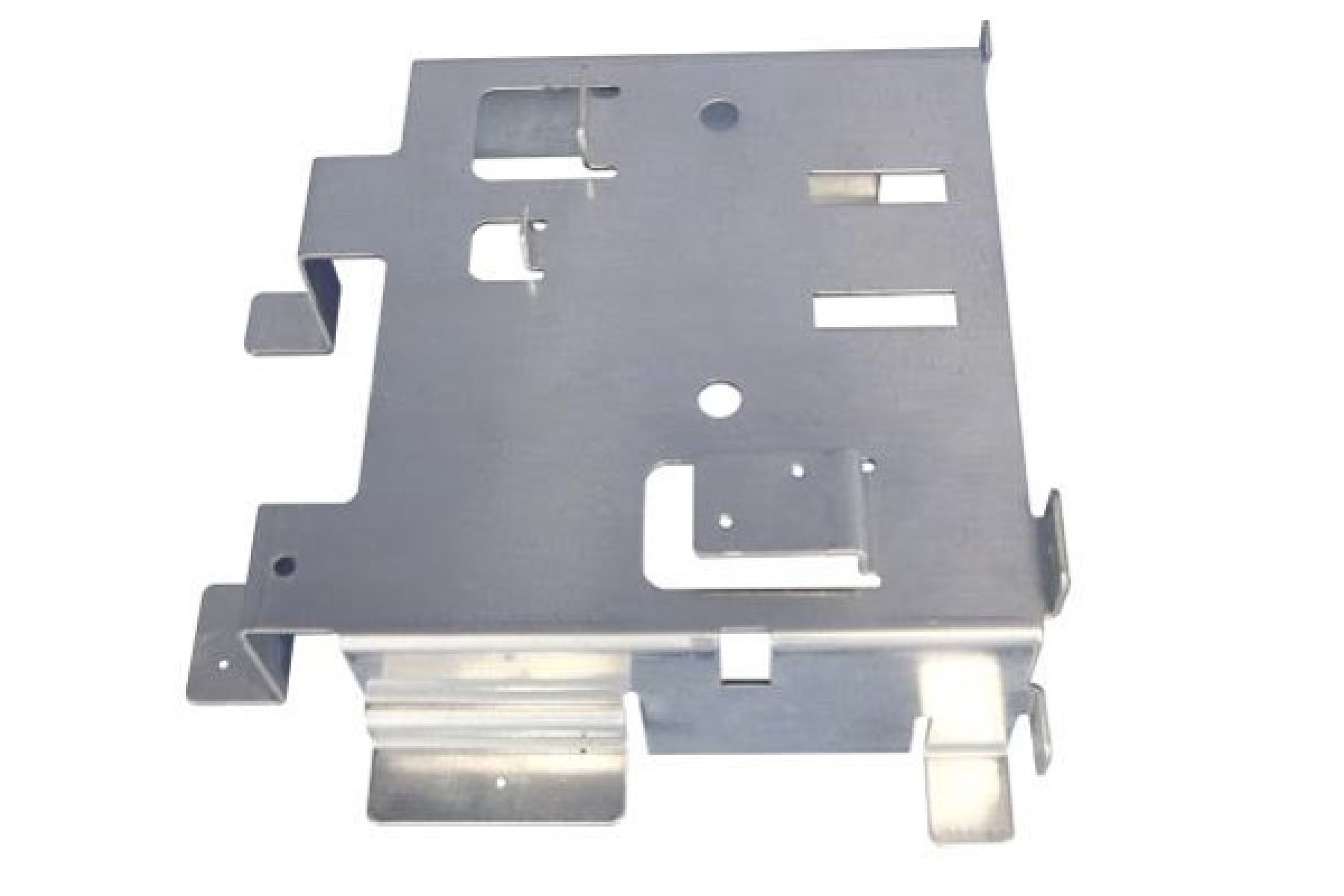

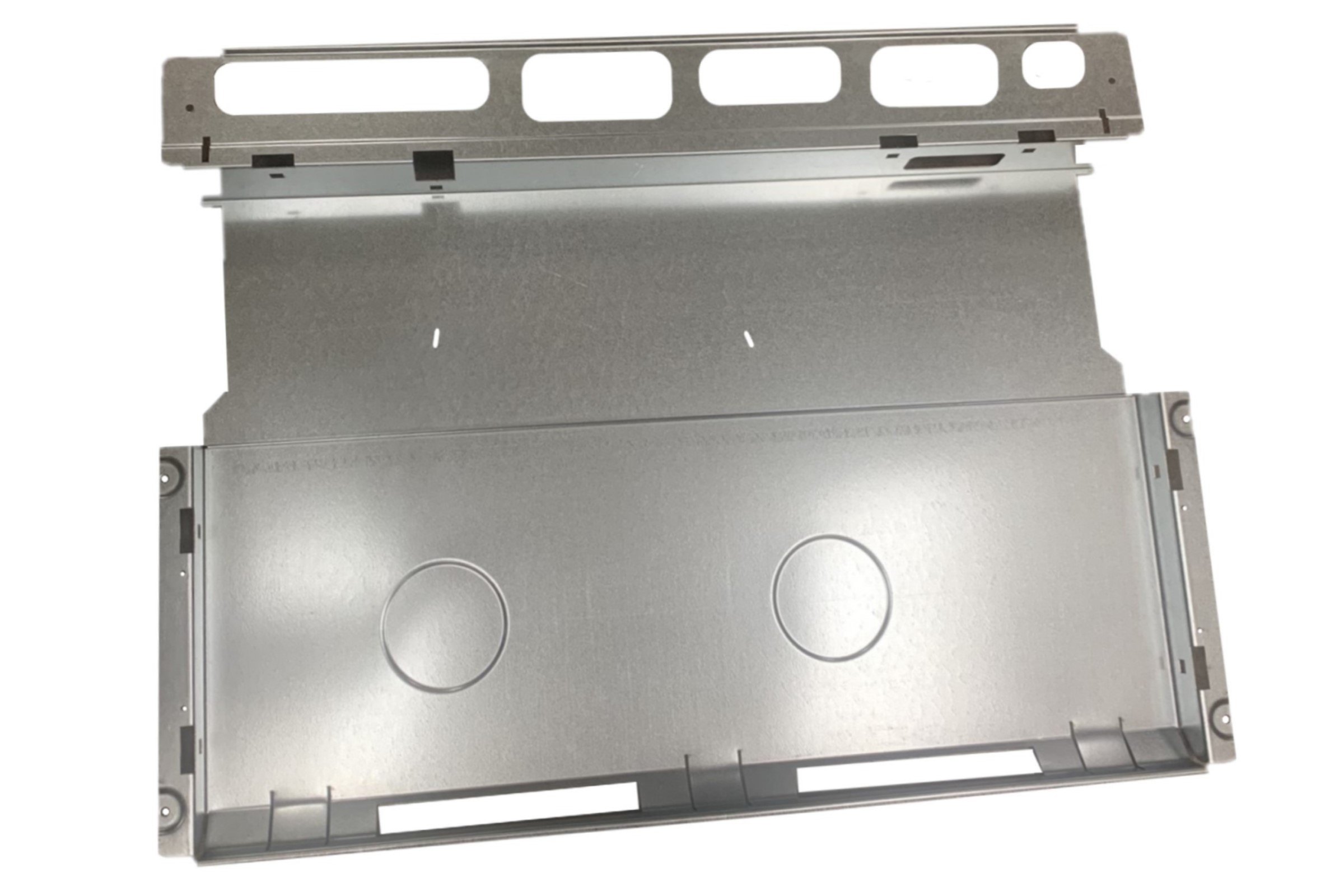

STAMPED METAL

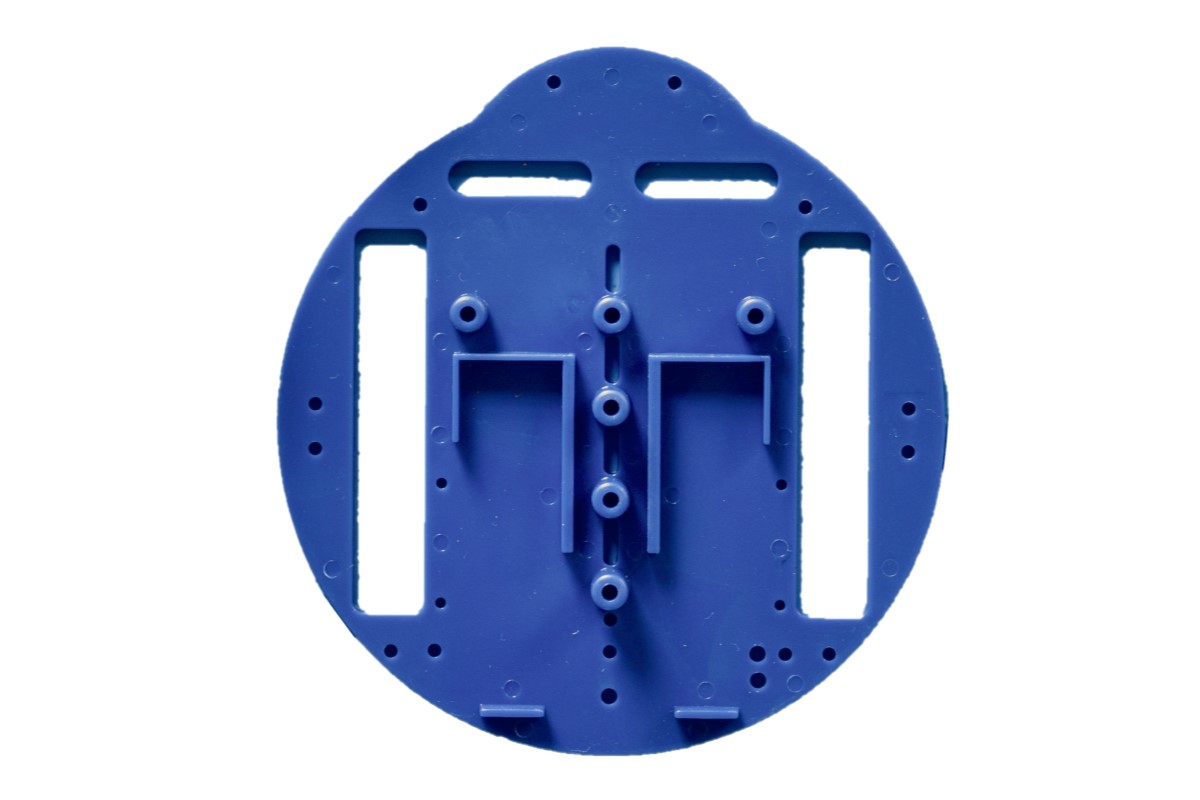

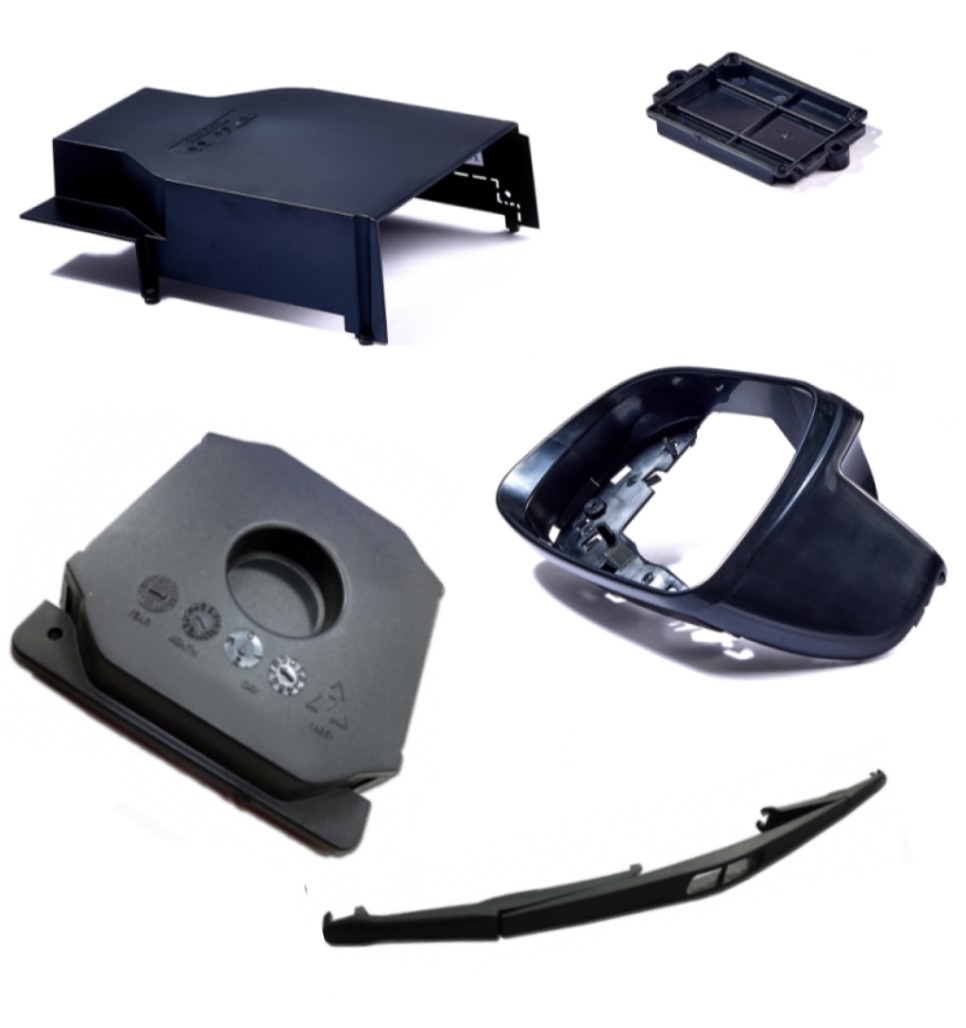

MOLDED PLASTIC

WHY CHOOSE FKI AS YOUR MANUFACTURING PARTNER?

You have an excellent idea for a product and now need it manufactured. You can manufacture in-house, which requires capital, people, and time. FKI can provide you with the finest manufacturing solutions, known as private labeling. Our customers gain significant value and fewer headaches. Our global resources allow you to concentrate on marketing, developing the brand, and selling. Utilize our materials, inventory, infrastructure, and expertise, benefiting you to allow improved flexibility and higher margins. From simple to elaborate, we deliver exceptional products at an affordable price.

BENEFITS

COST SAVINGS

FKI can save money by not having to provide the expensive overhead to manufacture products in-house.

AVAILABILITY OF SPECIALIZED SKILLS

FKI provides access to our engineering, design and manufacturing resources, specialized knowledge that may not be easily or cost effectively available.

EASY TO SCALE PRODUCTION

FKI has the resources and expertise to handle high volume production runs, so when the big order comes in, we can quickly scale to support the opportunity.

FOCUS ON CORE COMPETENCIES

FKI is the manufacturing expert, allowing companies to focus on their core competencies. This can help businesses stay competitive and scale quickly.

QUALITY CONTROL

FKI has over 40 years of manufacturing experience for many fortune 500 companies. We understand the cost of quality assurance and can ensure that products meet the standards.

REDUCE RISK

FKI can help businesses reduce risk by reducing start up capital and avoiding the need to invest in expensive equipment or hire additional staff.

METAL COMPONENTS

Dryer Vent – Hand Transfer

CAPABILITIES

• Over 620 metal stamping presses worldwide.

• 60 Ton up to 2000 Ton

• Presses Beds up to 72″ x 177″

• Progressive & Transfer Stamping

• Class A High Cosmetic products

• Deep Draw stamping of larger components

• In-House Tooling fabrication & Maintenance

• World-class manufacturing from multiple locations overseas or from our US facility

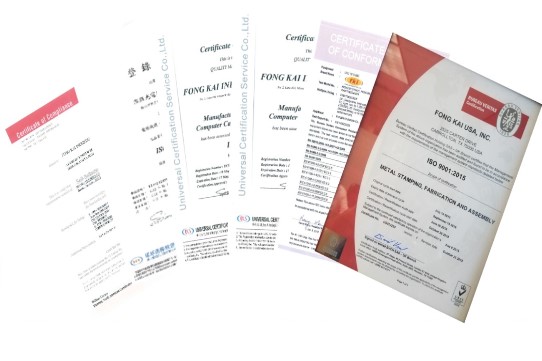

• All stamping facilities are certified (ISO 9001) in 2015.

ADDITIONAL FEATURES INCLUDE, BUT NOT LIMITED TO:

Assembly, Wet and Dry Coatings, Printing, Tapping, Coating, Deburring, Plating, and PVD Coating

MATERIALS

• Stainless Steel

• Aluminum

• Cold Rolled Steel

• Pre-coated Steel & Aluminum

• Electro-Galvanized

• Aluminized Steel

• Enameled Steels

• Bright, Brushed, or Mill Finish

• High Strength Low Alloy Material

PLASTIC COMPONENTS

CAPABILITIES

• 400 plus injection molding machines worldwide

• Presses up to 1600 tons

• Sizes up to 85″ LCD Screens and 5KG shots possible

• Class A Decorative Cosmetic finishes

• Specializing in High Cosmetic finishes on larger components

• Pad Printing and Silk Screen Processing

• In-House Tooling fabrication & Maintenance

• Overseas Qualifications available

• World-class manufacturing from multiple locations overseas

• All our injection molding facilities are certified (ISO 9001) 2015

ADDITIONAL FEATURES INCLUDE, BUT NOT LIMITED TO:

Paint Wet and Dry application, Multi-Material Multi-Shot, Plating and CNC Machining

MATERIALS

• ABS – Acrylonitrile Butadiene Styrene

• PE – Polyethylene

• PC – Polycarbonates

• PET – Polystyrene

• PP – Polypropylene

• HIPPS – High Impact Polystyrene

• Nylon

• Proprietary Polymers

HOW IT IS MADE

MOVING & STATIONARY ASSEMBLY LINES

Moving lines are used when parts are added as a semi-finished assembly moves from station to station, and parts are added in sequence until the final assembly is produced.

Stationary lines are used when components are assembled at a fixed location, and the workers move from one station to the next to complete the assembly.

Our team of engineers can help determine the best production method, taking into consideration quantity, complexity, flexibility, and costs.

THE FKI ADVANTAGE

QUALITY &

CERTIFICATIONS

LEARN MORE

GLOBAL LOGISTICS &

PLANNING

LEARN MORE