EXPLORE THE CAPABILITIES

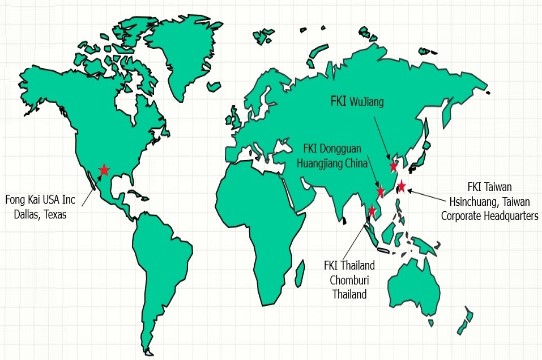

GET STARTED TODAYWith over four decades of experience supporting industrial applications, FKI is well-positioned to support climate control mechanical programs. We excel in manufacturing mechanical products for the HVAC markets. Our team commonly develops products using mild steel, high-strength steels, alloy steel, stainless steel, aluminum, cold rolled, pre-coated steels, electro-galvanized, and enameling steels. Our expertise and engineering capabilities can meet customers’ expectations on many products commonly used in HVAC applications. We handle all phases of development, including new product design, tooling design, tooling fabrication, metal stamping, plastic injection molding, finishing, part assembly, packaging, part decoration, LCC integration, and logistics. Working with FKI gets you results, ultimately lower costs, more value, and reduced risk. Our team is positioned to support Mid-high volume and complex components for HVAC, including:

VENTS

DOORS

COVERS

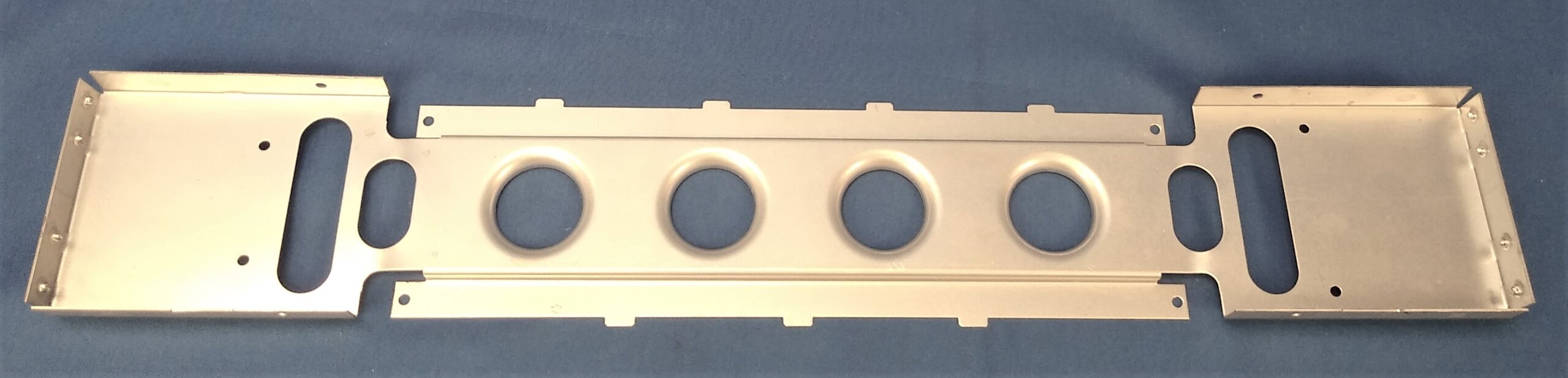

PANELS

BRACKETS

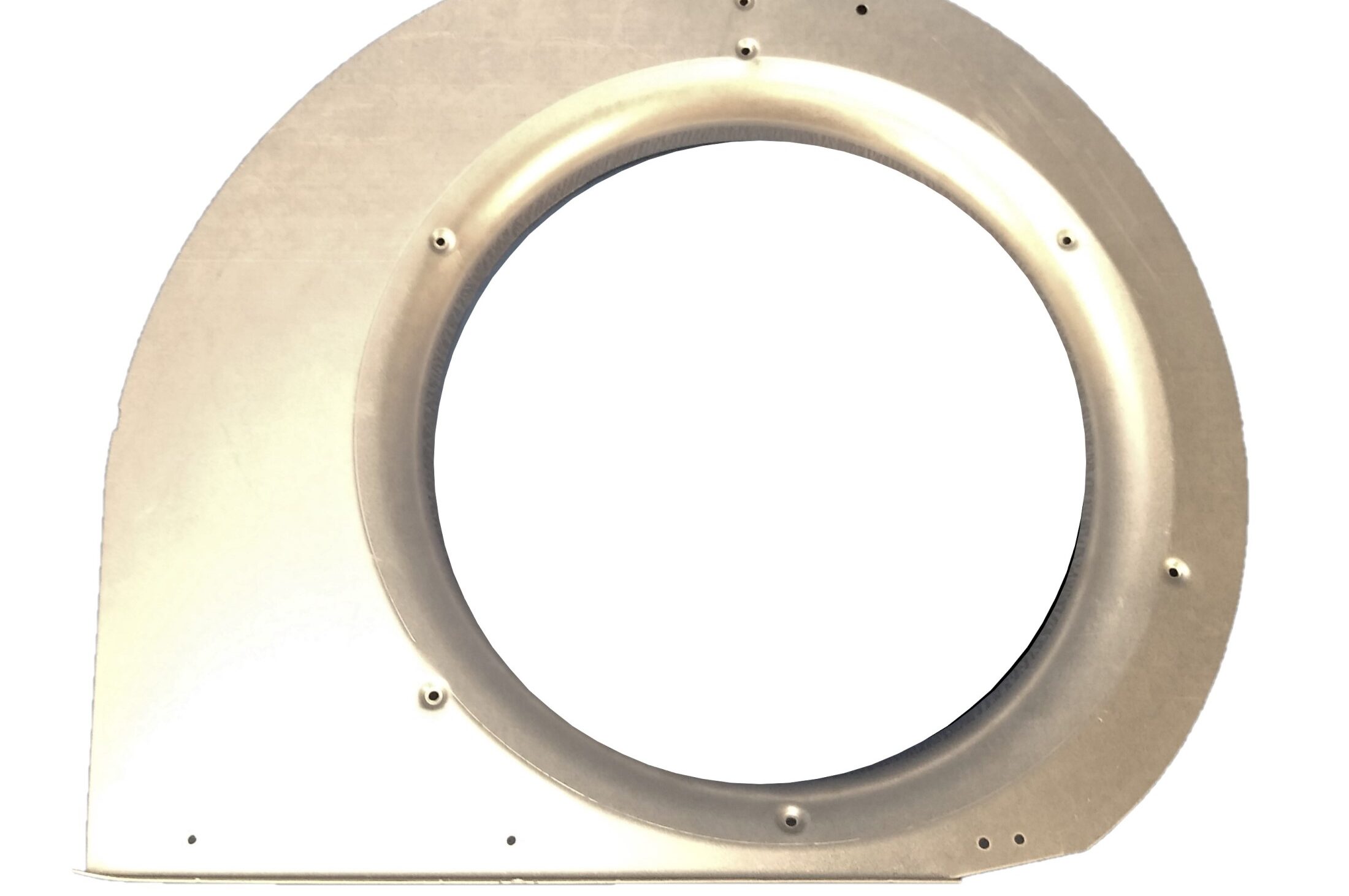

HOUSINGS

METAL COMPONENTS

Metal products are cost-effective and provide years of service for HVAC applications. They improve the aesthetic appeal of the product and align with your branding. In addition, they offer durability and strength and can resist rust, fire, heat, wear, and corrosion. With their high thermal operating range and relatively low cost, they are the most commonly used material in HVAC applications. Together we will help you produce a cost-effective, high-quality part that meets or exceeds your needs.

CAPABILITIES

• Over 620 metal stamping presses worldwide.

• 60 Ton up to 2000 Ton

• Presses Beds up to 72″ x 177″

• Progressive & Transfer Stamping

• Class A Cosmetic products

• Specializing in Deep Draw stamping of larger components

• In-House Tooling Build & Maintenance

• US Qualifications available to reduce overseas travel of Engineering Resources

• World-class manufacturing from multiple locations overseas or from our US facility

• All stamping facilities are certified (ISO 9001) in 2015 or better.

ADDITIONAL FEATURES INCLUDE, BUT NOT LIMITED TO:

• Fittings, Finishing, Forming, Flanges Deburring, Painting, Powder Coating, and PVD Coating

MATERIALS

• Stainless Steel

• Aluminum

• Cold Rolled Steel

• Pre-coated Steel & Aluminum

• Electro-Galvanized

• Aluminized Steel

• Enameled Steels

• Bright, Brushed, or Mill Finish

• High Strength Low Alloy Material

OEM PRODUCTS

Vents, Ducts, Blower Motor Housing, Condenser Coil components, Pans, Covers, Motor Housings, Panels, Deep Drawn Housings, Duct Fittings, Frames, Reservoirs, Enclosures, Plenum Boxes, Door Panels, Brackets, Pump Housings, Weldments

SUPPORTING DEVELOPMENTS

• Complete Turnkey Project Management

• FKI can support Multiple Tool Package Developments from internal and external suppliers/customers

• Virtual Design Review

• PPAP- US Qualifications Available to Reduce Overseas Travel of Engineering Resources

• Welding, Test Fixture, and Jig Development in Accredited Certified Facilities

• Simulation Validation and Reporting

• Laser Welded Fabrication

• Build to Print

• Weldments and Assemblies

• Utilizing Fully Licensed 3D CAD software

• Zeiss CMM with Calypso

• Hexagon Laser Scanning and PC Dimis inspection software

HOW IT’S MADE

Stamping is excellent for larger quantities due to its efficiency and affordability in mass quantity.

WATCH VIDEO

THE FKI ADVANTAGE

QUALITY &

CERTIFICATIONS

LEARN MORE

GLOBAL LOGISTICS &

PLANNING

LEARN MORE