EXPLORE THE CAPABILITIES

GET STARTED TODAYOur plastic parts, housings, and enclosures are some of the finest in the industry. We specialize in precision plastic injection molding products for Consumer Electronics, Computing, industrial, appliance, automotive, and commercial applications. Our molded parts can be small or as large as an 85” LCD TV enclosure. We have over 420 injection molding machines company-wide. We use hydraulic, electric, and hybrid injection molding machines to make our products of high quality. Using servo robotics throughout the highly automated process helps reduce manufacturing costs and increases quality. Our machines range in size from 50 tons up to 2000 tons. All our plastics manufacturing is done overseas, and we offer direct shipments or USA warehousing.

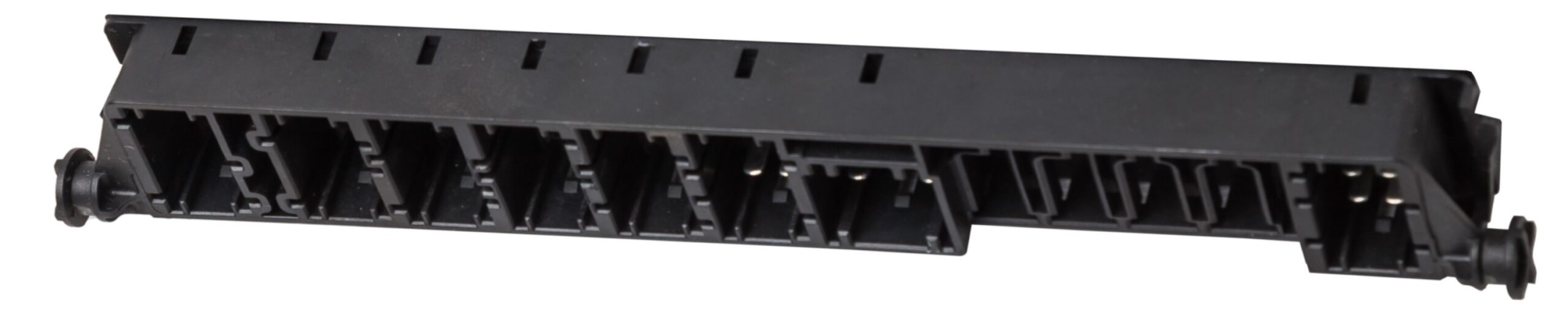

PLASTIC COMPONENTS

Molded plastic components are used in an assortment of products. Plastics improve a product’s durability, functionality, visual appeal, and affordability. These plastic components are crucial for many industries because they offer many advantages over other materials. Plastics are lightweight, customizable, and can enhance product performance.

OEM PRODUCTS

• Copier Components

• Printer Components

• Display Fronts

• Display Backs

• LED Shade

• Liquid Crystal TV components

• Automotive Parts

• Door handles

• Control panels

• Housings

• Skins

• Panels

• Liners

• Pans

• Covers

• Trim

• Brackets

• Bases

CAPABILITIES

• 400 plus injection molding machines worldwide

• Presses up to 1600 tons

• Sizes up to 85″ LCD Screens and 5KG shots possible

• Class A Cosmetic finishes

• Specializing in High Cosmetic finishes on larger components

• Pad Printing and Silk Screen Processing

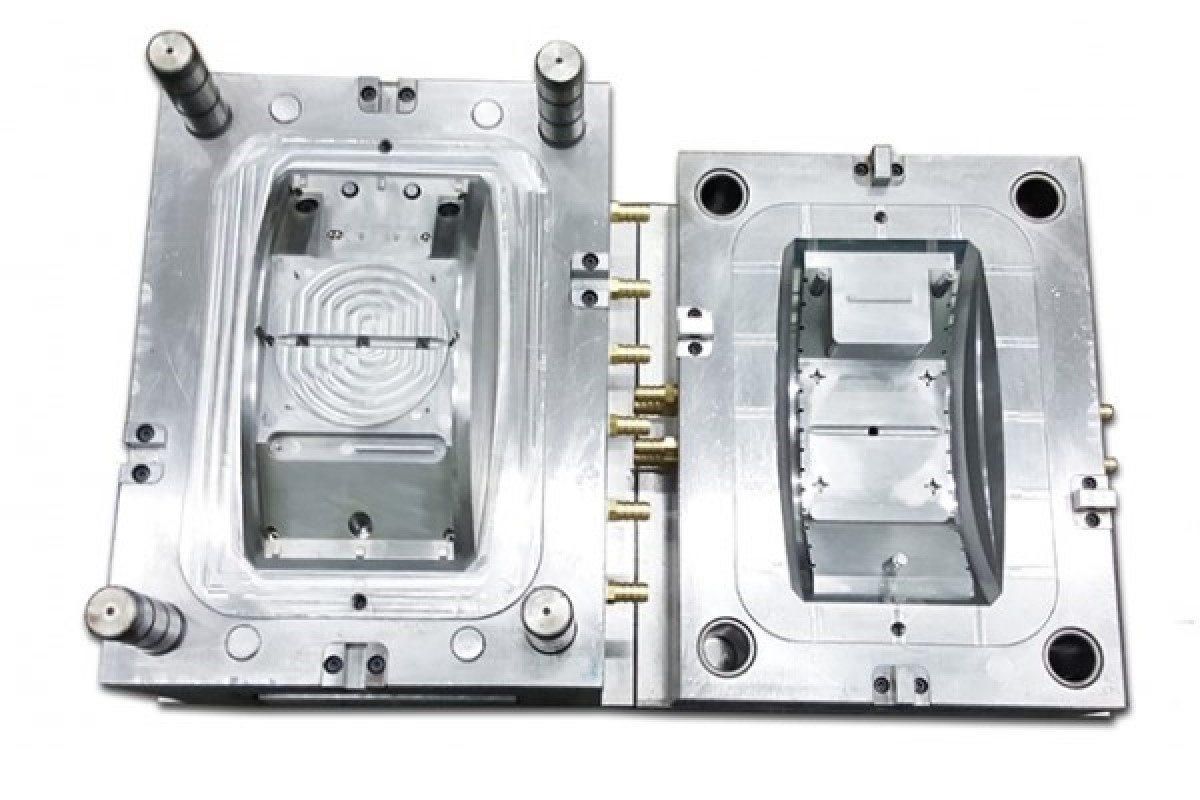

• In-House Tooling fabrication & Maintenance

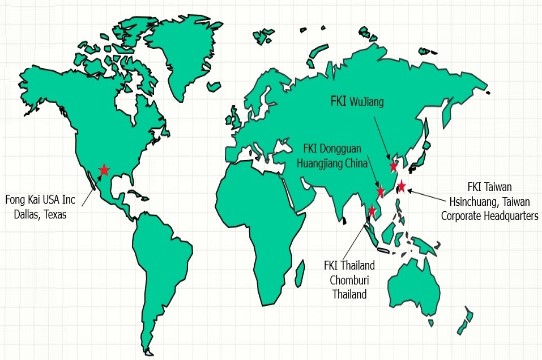

• World-class manufacturing from multiple locations, domestic and overseas

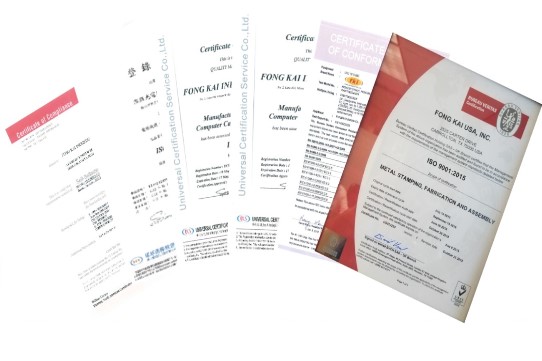

• All our injection molding facilities are certified (ISO 9001) 2015

ADDITIONAL FEATURES INCLUDE:

• Ultrasonic Welding, Assembly, Multi Shot Injection, Electroplating, Silk Screening and Pad Printing, Paint Wet and Dry Coating, and PVD Coating

MATERIALS

•All commonly Molded Polymers, including ABS, PE, PC, PET, PP, and Blends

• Structural Reinforced Polymers

• Proprietary Engineered Polymers

SUPPORTING DEVELOPMENTS

• Complete Turnkey Project Management

• FKI can handle large jobs from multiple suppliers/customers

• Virtual Tool / Product Design Review

• Weldments and Assemblies

• Build to Print

• Additional features but not limited to Fittings, Finishing, Deburring, Painting, Powder Coating, Forming, and Flanges

• 3D CAD software is preferred file extensions: PRT, IGES, STEP, DXF or DWG, SLDPRT, SAT, and STL

QUALITY & CERTIFICATIONS

All our stamping facilities are ISO certified (ISO 9001) and specialists in UL, CSA, NSF, CE, and ETL standards.

HOW IT’S MADE

It all starts with a mold typically machined from steel or aluminum. The type of metal and process of making a mold will depend on the part’s lifespan, size, complexity, and the kind of plastic needed. Both 2D and 3D shapes can be made from plastics with intricate detail. A thermoplastic is fed into an injection molding machine, plastic is heated, and then forced into a metal mold where it conforms to the shape of the cavity. The hot plastic is then cooled, and the hardened plastic is removed from the mold. The plastic part can undergo several secondary operations, like machining, powder coating, PVD coating, silkscreen, plating, sonic welding, and assembly. We specialize in large, high-quality cosmetic and unique polymer products and offer a great value proposition to our partners.

WATCH VIDEO

THE FKI ADVANTAGE

QUALITY & CERTIFICATIONS

LEARN MORE

GLOBAL LOGISTICS & PLANNING

LEARN MORE