EXPLORE THE CAPABILITIES

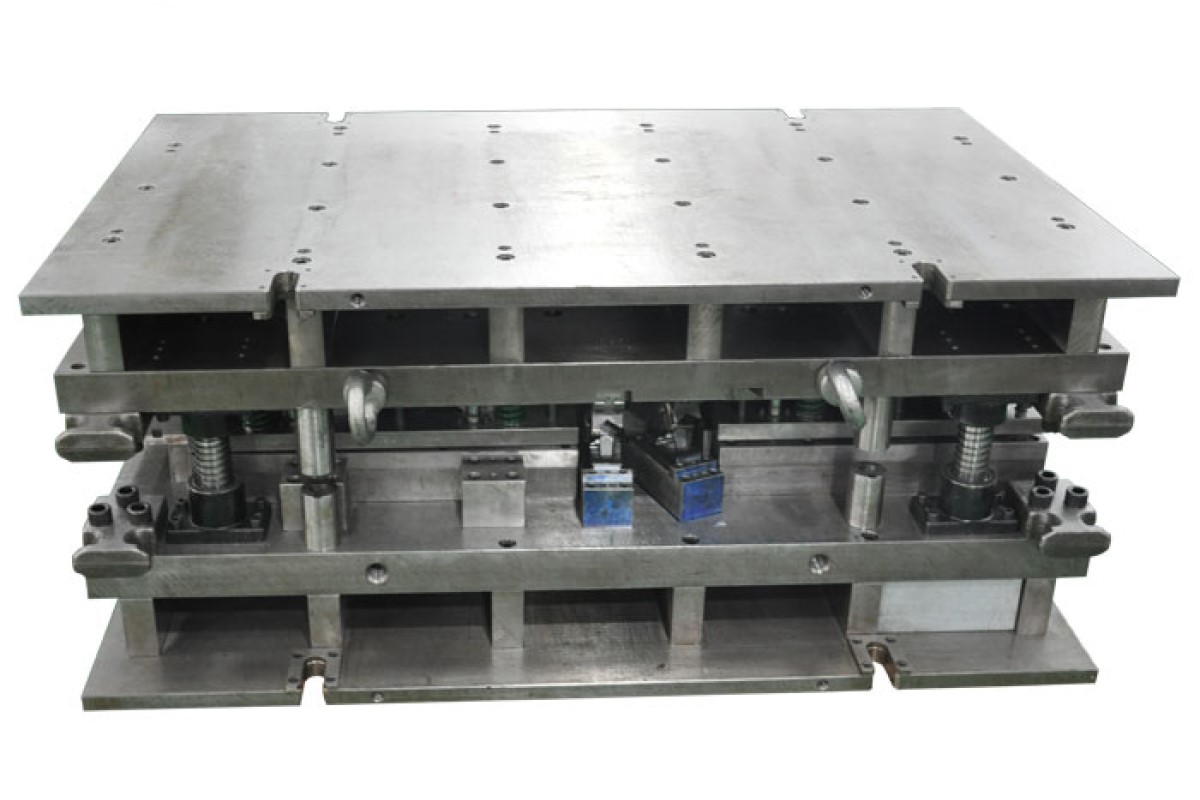

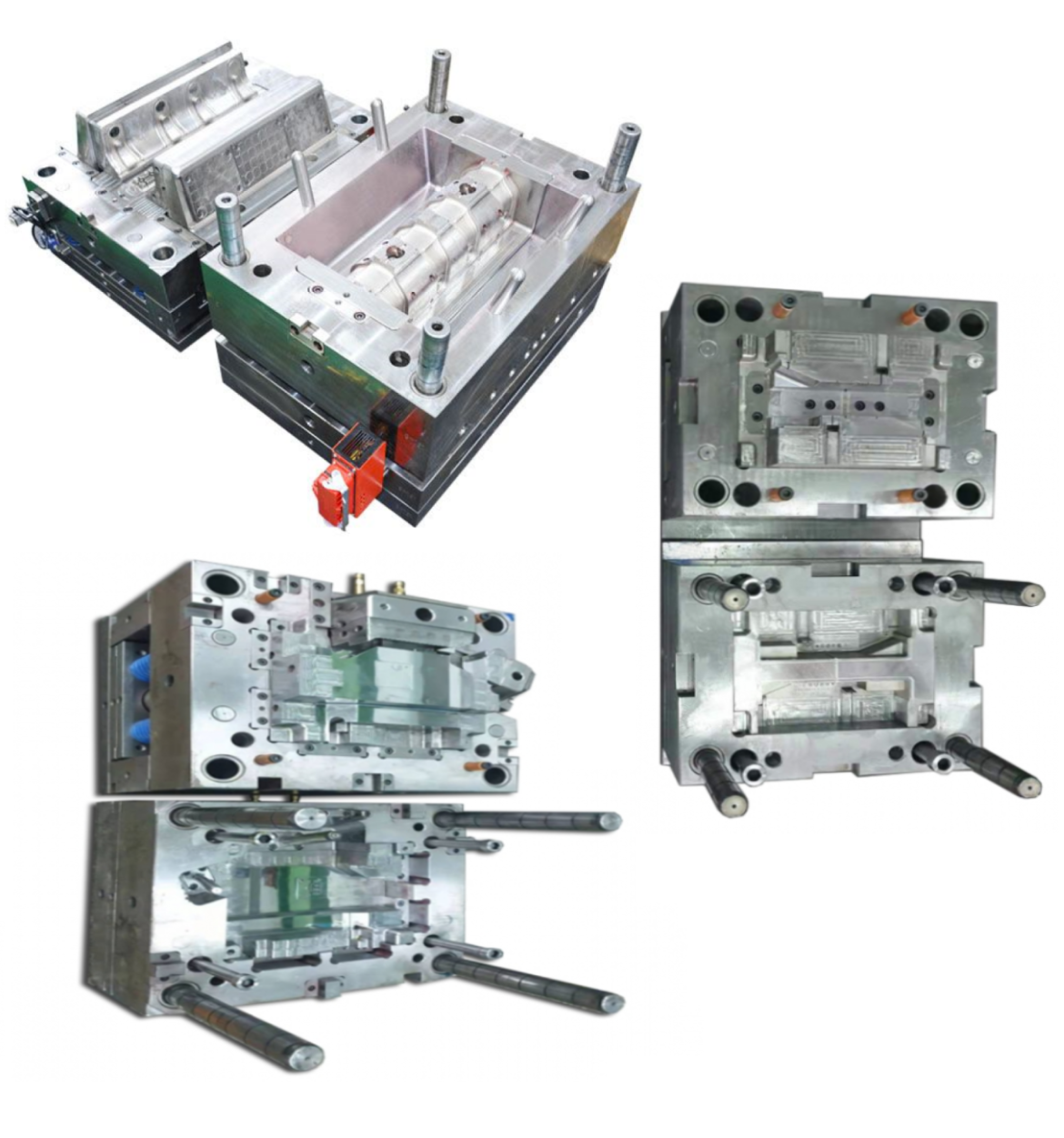

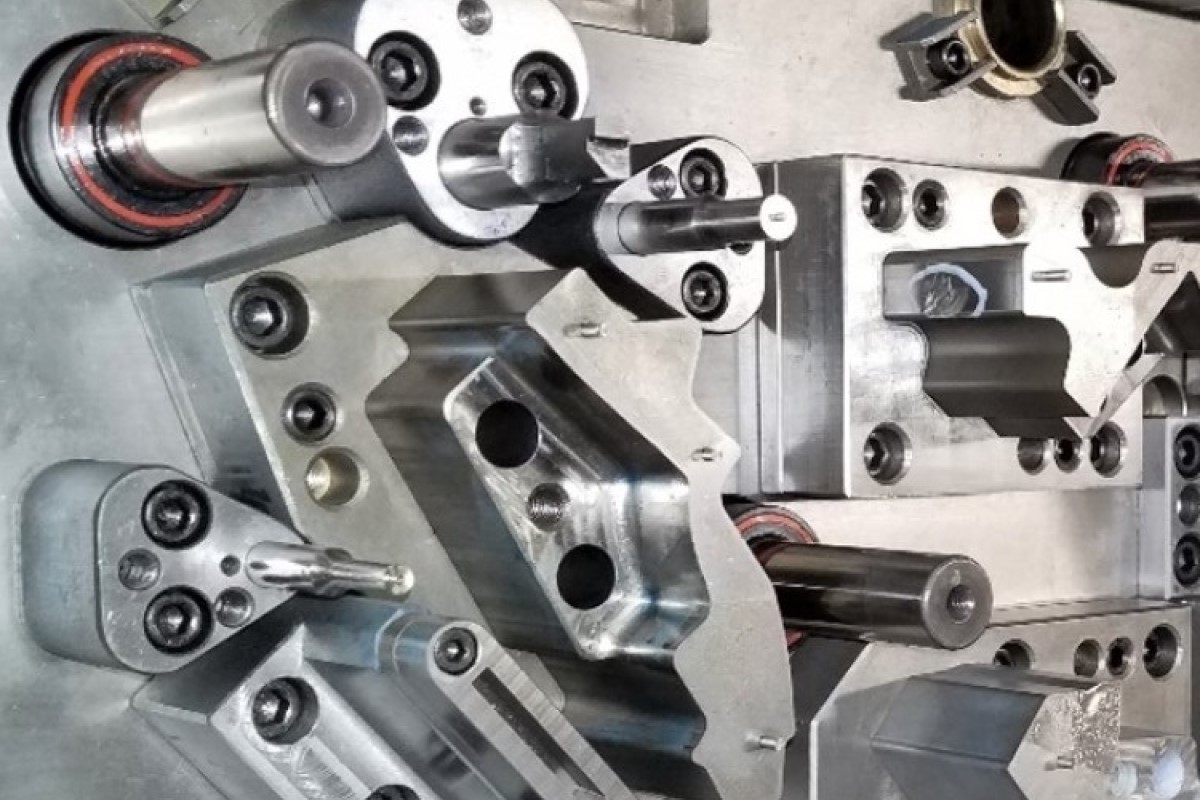

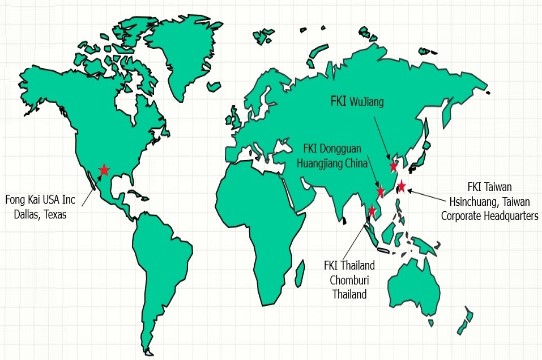

GET STARTED TODAYFKI is an experienced tool and die manufacturer of metal stamping and injection mold tooling. Tools are manufactured worldwide in our state-of-the-art facilities. All five stamping plants have a full-service, in-house toolroom. We design, engineer, and produce progressive, transfer, and deep-draw stamping tooling for internal customers and manufacturers worldwide.

CNC

MILLING

CNC

TURNING

CNC

PARTS

STAMPING

TOOLING

INJECTION

MOLDING

TOOLING

EDM WIRE

CUTTING

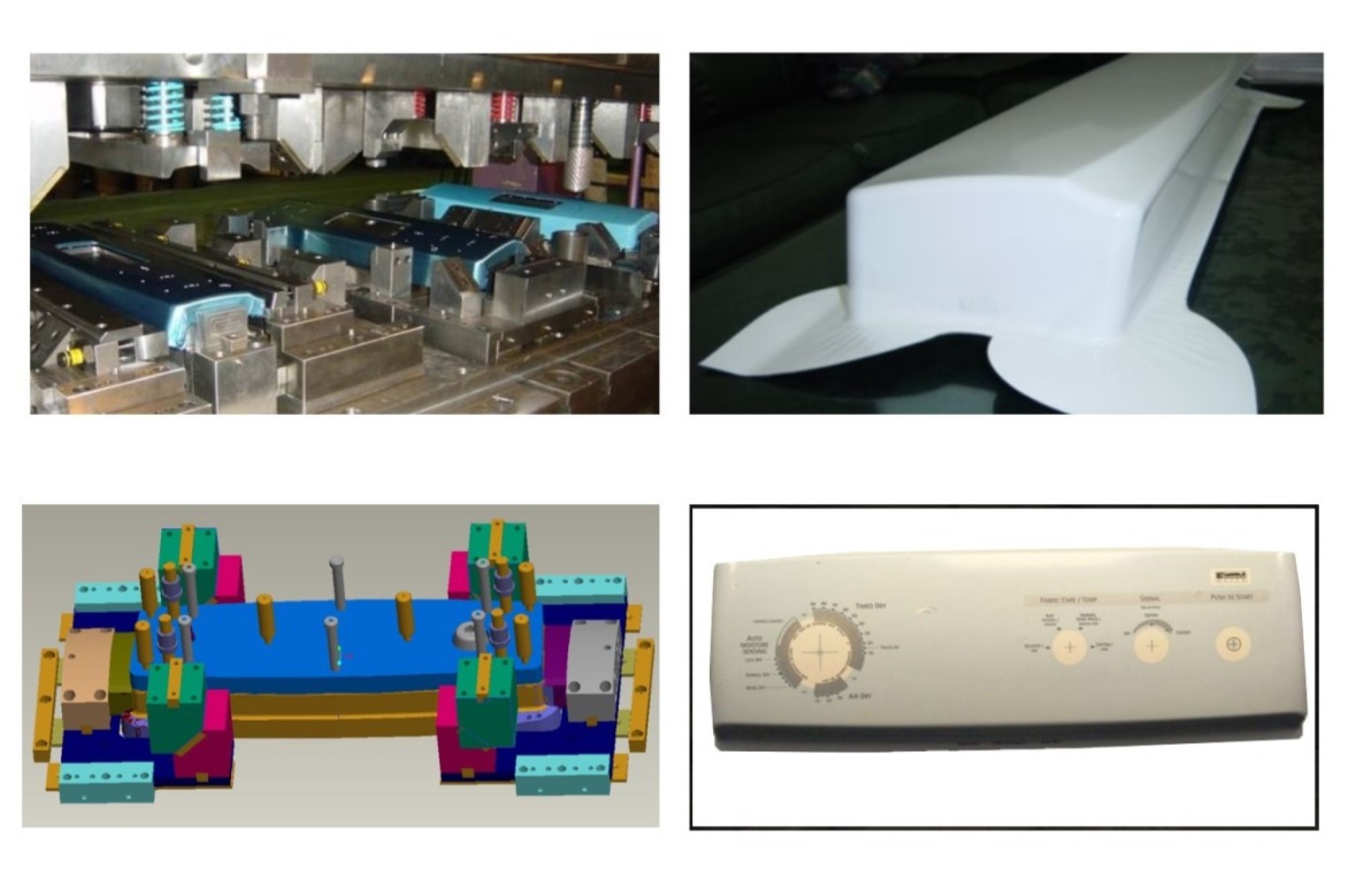

TOOLING PLAN

FKI is an experienced tool and die manufacturer of metal stamping and injection mold tooling. Tools are manufactured worldwide in our state-of-the-art facilities. All five stamping plants have a full-service, in-house toolroom. We design, engineer, and produce progressive, transfer, and deep-draw stamping tooling for internal customers and manufacturers worldwide. Recognizing a proper tooling plan for a project is vital to efficiently implementing a new product. Before investing in production tools, a new part design usually starts with soft tooling a prototype to assure manufacturability. The initial prototype parts can typically be 3D printed, CNC machined, or injection molded. Once a part design is locked or stable, capital expenditure on production tooling can produce higher quantities at a reduced unit cost. Many factors must be considered when considering tooling, including the cost, complexity, and time to build the tool. All must be considered to satisfy the customer’s needs. In addition, we can predict how any future design changes will impact your tooling decision. Many situations require a phased approach where we build soft or temporary tools before upgrading to mass-production tooling. This helps reduce the risk associated with some projects.

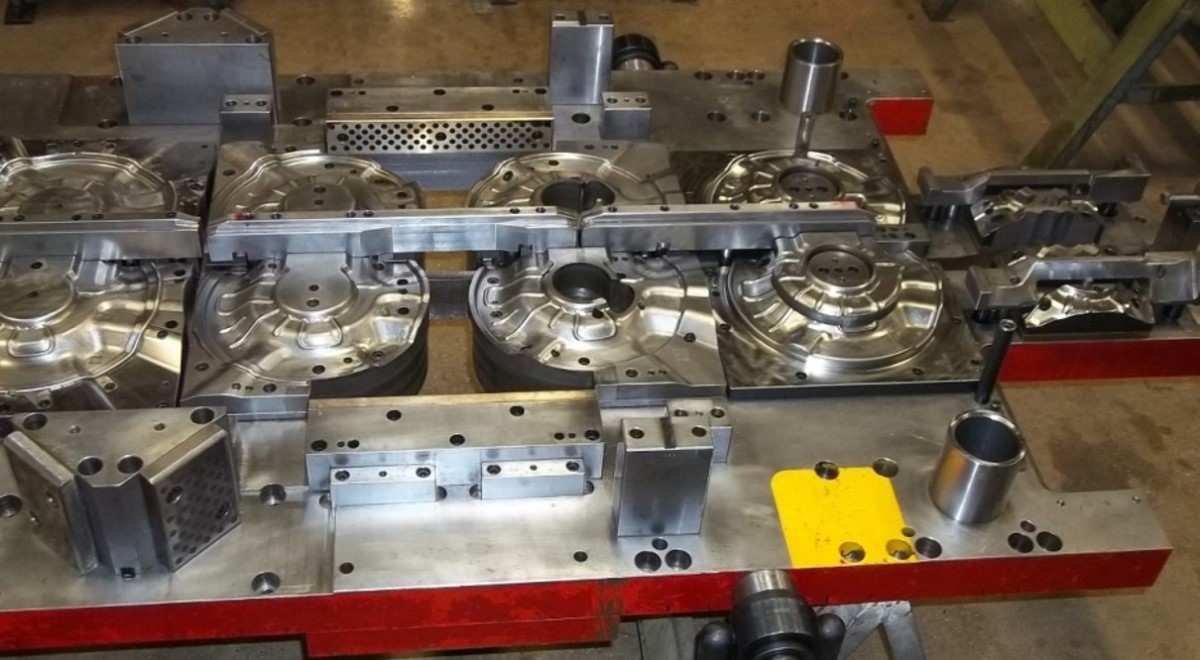

TOOLING & DIE SERVICE

1500 + Machines Worldwide

Milling, Cutting & Finishing

EDM

CNC Machining

CNC Turning

Multi-Axis Milling

Swiss Turning

Electropolishing

Plating

Heat Treating

Laser Welding

Surface Grinding

Centerless Grinding

Lapping

Deburring

Wave Shear Grinding

Jigs

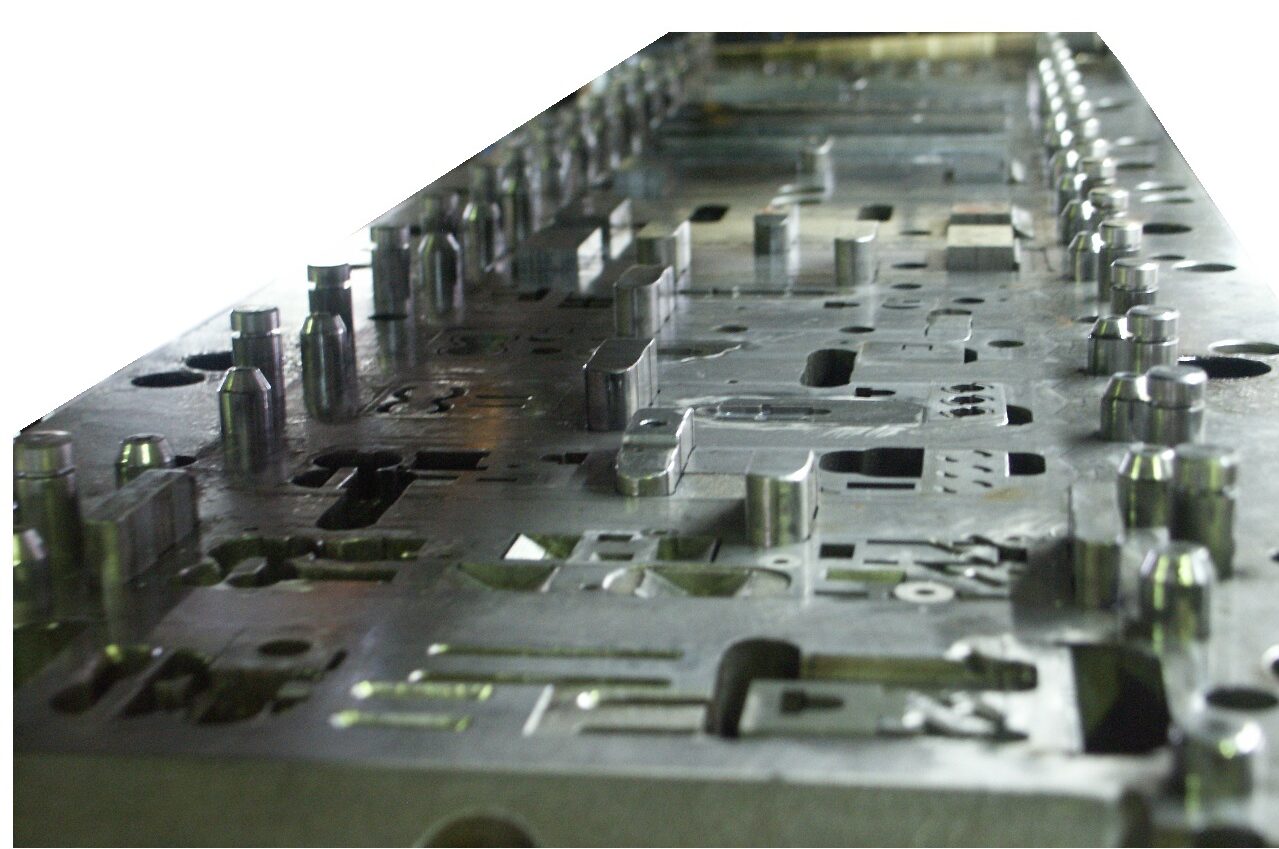

DESIGNING A METAL STAMPED PART

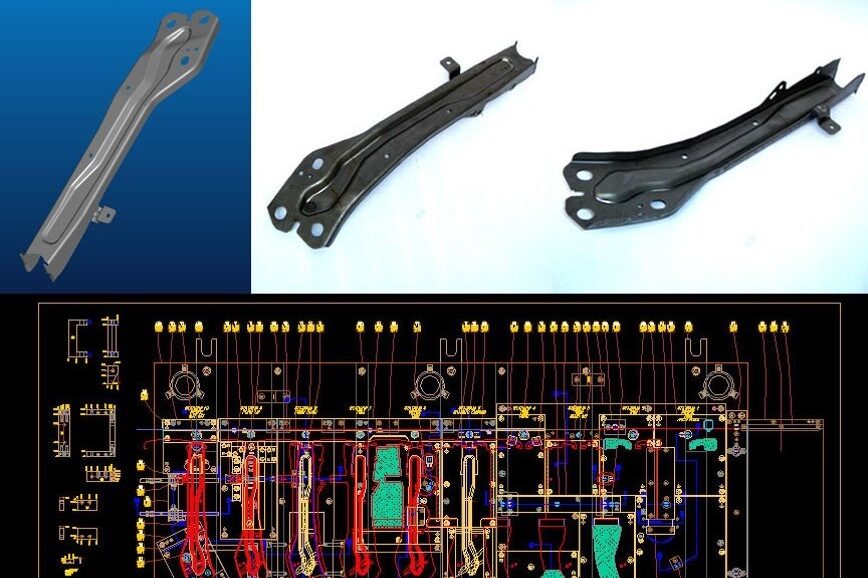

When our team of expert engineers at FKI embarks on designing a stamped metal component, we take into account several crucial factors. These include the function or purpose of the component, its durability, the design of the die, the part size, and the feasibility of mass production. Our unwavering commitment is to help you design the most effective solution for your needs, and we can recommend the most suitable and cost-effective solution for your application.

Take, for instance, the HVAC modular attachment bracket we manufactured at FKI. Using a 13-station progressive stamping tool, we crafted this bracket from 1.5mm steel, showcasing our ability to produce high-quality, precision parts.

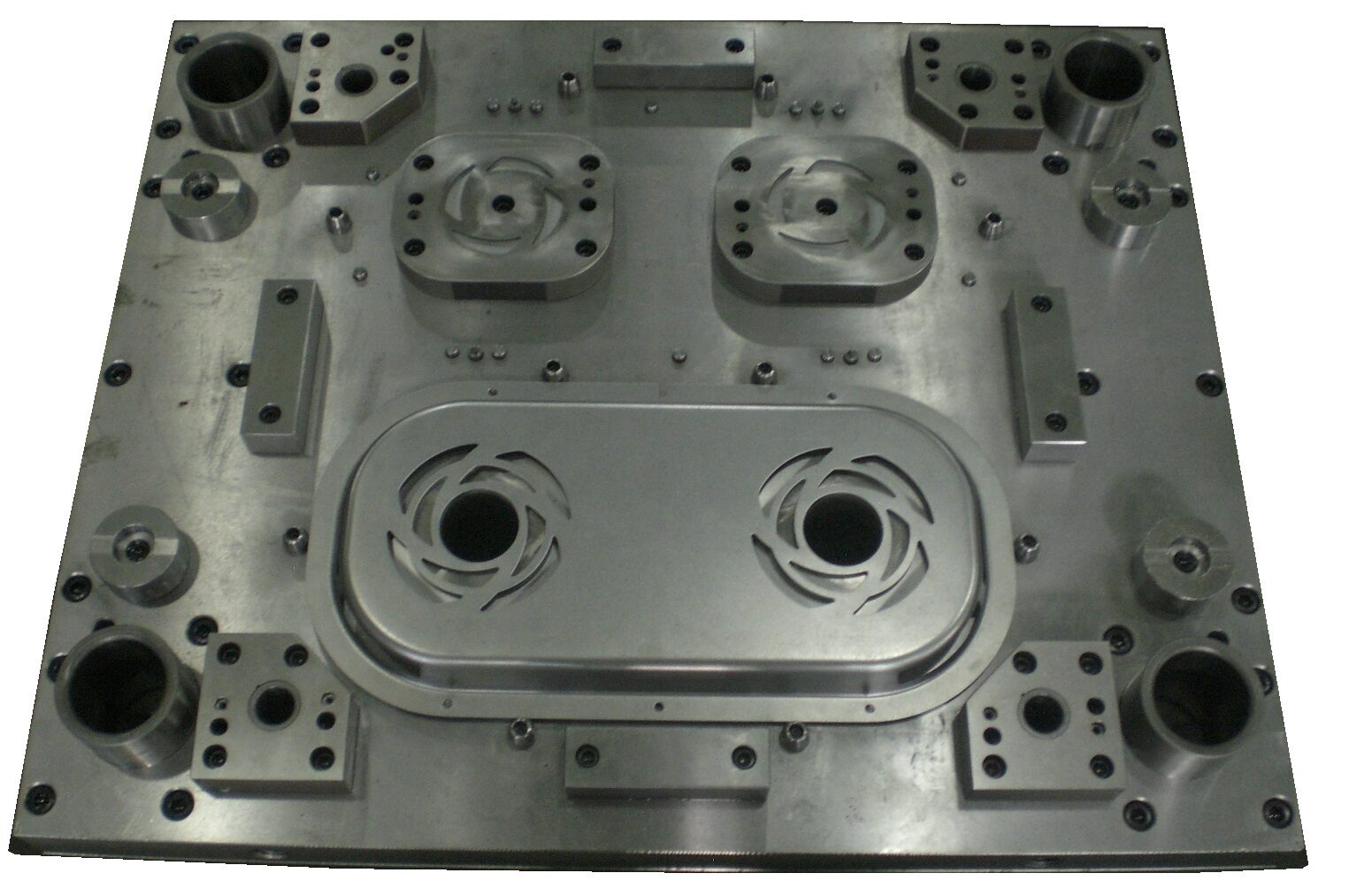

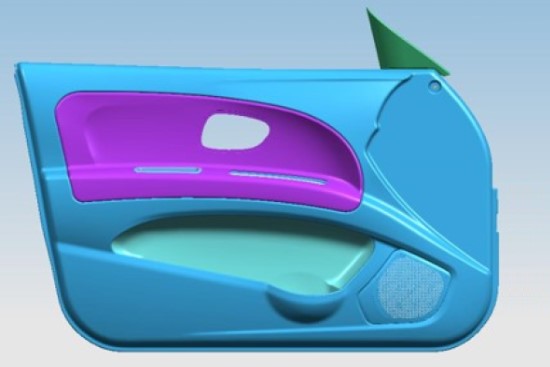

DESIGNING A PLASTIC INJECTION MOLDED PART

Designing a plastic component requires careful consideration of many factors, including application, desired material, part size, volume, and cosmetic standards. We can offer injection molding, blow molding, or thermoforming, and our engineers can help your team design a quality part. We assist you in choosing the proper material and can consider factors like heat resistance, durability, and strength. Most importantly, our staff can help ensure the part can be manufactured effectively in mass quantities at a reasonable price.

CAPABILITIES & PRODUCTION EQUIPMENT

620 + STAMPING PRESSES WORLDWIDE

• 60 Ton up to 2000 Ton

• Presses Beds up to 72″ x 177″

• Progressive & Transfer Stamping

• Class A Cosmetic products

• Specializing in Deep Draw stamping of larger components

• In-House Tooling Build & Maintenance

• US Qualifications available to reduce overseas travel of Engineering Resources

• World-class manufacturing from multiple locations overseas or from our US facility

• All stamping facilities are certified (ISO 9001) in 2015 or better.

• Transfer Dies

• High Volume +1,000,000 Progressive Die Stamping

• Multi-Out Progressive Dies

• Long Run or Short Run Tools

• Precision Gages and Fixtures

• Fully Integrated Vision Systems

• Multi-Out Dies

• Precision Gages and Fixtures

• Automation for Tooling Systems

• Punches and Bushings

• Prototype Tooling

• Tungsten Carbide Dies

• Modular Stamping Dies

400 + INJECTION MOLDING MACHINES WORLDWIDE

• Presses up to 1600 tons

• Sizes up to 85″ LCD Screens and 5KG shots possible

• Class A Cosmetic finishes

• Specializing in High Cosmetic finishes on larger components

• Pad Printing and Silk Screen Processing

• In-House Tooling fabrication & Maintenance

• Overseas Qualifications available

• World-class manufacturing from multiple locations overseas

• All our injection molding facilities are certified (ISO 9001) 2015

OVERSEAS OR USA TOOLING BUILD

USA TOOLING

100% Domestic Build – Engineered, built, and qualified in Texas

OVERSEAS TOOLING

100% Offshore Tooling Build, and 100% offshore fabrication and Direct Shipment – Typically Lowest Cost Alternative

OVERSEAS TOOLING

100% Offshore Tooling Build, Offshore Fabrication and Domestic Qualification – Low Resource Impact, excellent Value

OVERSEAS TOOLING & DOMESTIC ASSEMBLY

Offshore Fabrication of Details and Domestic Assembly – Fastest Delivery, Lower Cost than 100% US Build

TOOLING STORAGE

At FKI, we store all customer-owned and FKI-owned stamping tools inside our secure climate-controlled facilities. We have thousands of tools in various sizes and shapes, some as large as 6 feet x 16 feet. Some of the more significant tools can be over 70,000 lbs

TOOLING TRANSFER PROGRAMS

Many of our valued customers have decided to refocus their operations and not do stamping in-house. If you find that stamping is not in your core competence and you need to apply resources elsewhere, consider FKI for a complete transfer of your stamping operations. Utilizing FKI as your contract stamper allows you to redeploy labor and capital, eliminate operational headaches, and streamline purchasing. We welcome the opportunity to evaluate your existing tooling and determine which of our stamping plants best suits your production needs.

HOW IT’S MADE

Designs are cut into the substrate using 3, 4 or 5 axis milling machines. At FKI we have multiple manufacturing facilities worldwide and each of our factories has the equipment in-house to make your designs come to life.

WATCH VIDEO

THE FKI ADVANTAGE

QUALITY &

CERTIFICATIONS

LEARN MORE

GLOBAL LOGISTICS &

PLANNING

LEARN MORE