EXPLORE THE CAPABILITIES

GET STARTED TODAYOur fully integrated quality process and our quality engineers utilize the latest technology to deliver accurate and repeatable results in all business areas. Our commitment is demonstrated in our ability to provide innovation, technology, certifications, state-of-the-art facilities, and people. These essential parts allow us to meet or exceed the exacting industry standards and exceed our client’s expectations.

Our facilities meet or exceed ISO 9001-14001 and OHSAS 1800-certified quality systems. In addition, FKI is compliant and maintains UL, CSA, NSF, and CE registration. We can comply with and document material certifications, ITAR, and RoHS compliance. We conform to the following standards IPC A-610 – standard manufacturability of electronic assemblies

• IPC/WHMA A-620 standards – cable and wire harness assembly

• IPC A-630 – standards for manufacture

• IPC A-630 – Standards for inspection

• IPC A-630 – Standards for testing of Electronic Enclosures,

In addition, several of our overseas factories are compliant with all aspects of automotive parts manufacturing, including APQU, IATF 16949, PPAP, PMMEA, and PCN.1

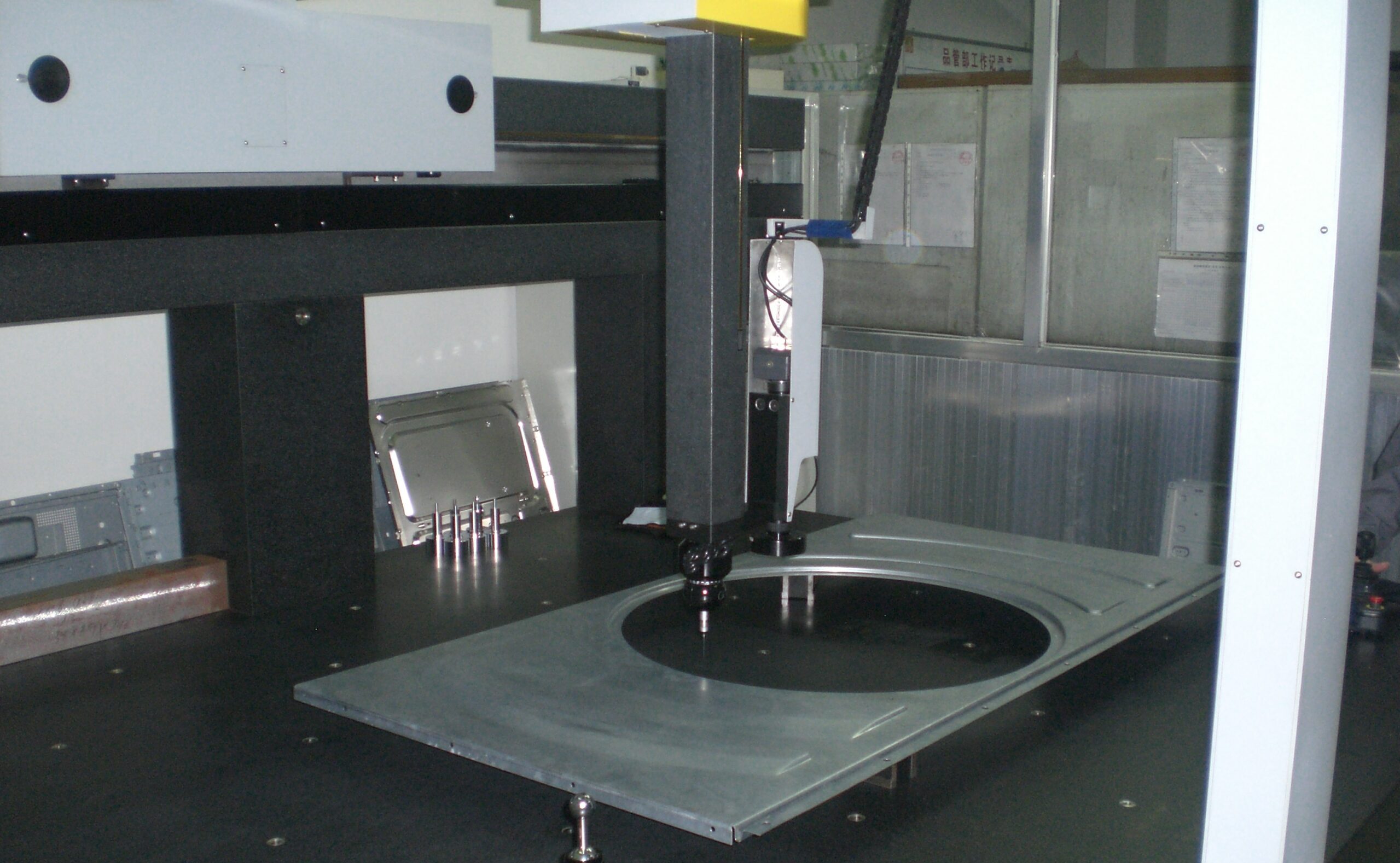

Coordinate Measuring Machine (CMM)

QUALITY OBJECTIVES

• Zero Escapes Measured in Parts per Million

• One Hundred Percent on Time Delivery

• Zero Customer Requested Corrective Actions

QUALITY POLICY

FKI is committed to producing quality products on time and to the satisfaction of our customers through continual improvement of its products and the Quality Management System.

ENVIRONMENTAL POLICY

Develop products that provide reduced environmental impact to the world in order to allow future generations to have an improved quality of life.

QUALITY INSPECTION

All our labs are staffed with a fully accredited quality engineering team that continuously improves our documentation and part certification process. Our quality team, along with every team member at FKI, is responsible for embracing and ensuring that quality is built into everything we do. We are dedicated to working with you from FAI/PPAP through your ongoing production needs.

3D SCANNING

This latest technology is utilized directly on our shop floor and requires no CNC programming. The flexibility of measuring on the shop floor improves efficiency and shortens the production process. The 3D cameras can identify, collect, and measure over 750,000 points per second. These points are joined to display a digital image of the scanned part.

ABSOLUTE ARM

• Laser scanning up to 10 times faster than traditional CMM

• Up to 2 microns’ accuracy

• Ease of learn & easy use

• Simple or complex geometries

• Portable or stationary

• Measure any size & shape

APPLICATIONS

• Tooling Design

• Machined parts inspection

• Machined tooling inspection

• Sheet metal stamping inspection

• Sheet metal fabrication inspection

• Injection molding inspection

• Inspecting any manufactured part

• Part assembly management

TRADITIONAL CMM

Coordinate Measuring Machine (CMM) is the most commonly used inspection tool at FKI. These machines are highly accurate but are associated with high-cost maintenance, controlled lab environment, and calibration.

Zeiss CMM

• Size up to 72″ x 108″

• Traditional contact-based measuring tools

• Simple or complex geometries

• Stationary machines