EXPLORE THE CAPABILITIES

REQUEST A QUOTEIN THE BEGINNING

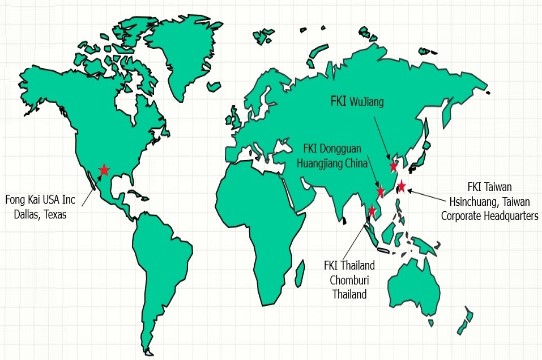

Established in Taiwan forty years ago, Fong Kai Industrial Companies (FKI) has grown to become a multinational contract manufacturing giant. Our factories are in 5 countries – Taiwan, China, Thailand, Vietnam, and the USA. Our footprint is over 1.77 million sq. Ft of manufacturing space worldwide. Initially, we engaged mainly in the contract manufacturing of computer hardware and chassis. In those early years, a large percentage of our business was manufacturing PC Enclosures. As the PC industry matured, we shifted our focus to designing, engineering, and fabricating servers, workstations, and integrated box builds.

BUSINESS EXPANSION

Before long, we made a wide range of complete electromechanical assemblies for many of the world’s leading technology companies and multinational brands. The business continued to grow and leverage its expertise in optoelectronics, wire harnesses, LED products, monitors, projectors, and input devices. Our business expanded into automotive metal stampings, appliances, and consumer electronics. Forty years later, FKI is still manufacturing, and our clients are among the world’s most trusted brands.

ENVIRONMENTAL POLICY

Utilize engineering and manufacturing products that reduce environmental impact on the world and allow future generations to have an improved quality of life.

BUSINESS PHILOSOPHY

Provide cost-effective, high-quality products to our manufacturing partners in a highly competitive industry.

QUALITY POLICY

FKI is committed to producing quality products on time and satisfying our customers by continually improving its products and quality management system.

QUALITY OBJECTIVES

• Zero Escapes Measured in Parts per Million

• One Hundred Percent on Time Delivery

• Zero Customer Requested Corrective Actions

BENEFITS OF WORKING WITH FKI

FKI can reduce costs by providing a global manufacturing footprint almost instantly. We maintain facilities in Taiwan, China, Thailand, Vietnam, and the USA. Whether you’re a startup or a seasoned corporation with years of manufacturing experience, FKI can provide a cost-effective quality product on time and within budget. These attributes can be beneficial for small businesses and startups with limited capital.

SPECIALIZED SKILLS

Access to our engineering, design, and manufacturing skills, specialized knowledge, and expertise.

EASY-TO-SCALE PRODUCTION

FKI is the manufacturer with the resources and expertise to handle large-scale production runs.

FOCUS ON CORE COMPETENCIES

As a manufacturing expert, we allow companies to focus on their core competencies. This can help businesses stay competitive and grow more quickly.

QUALITY CONTROL

FKI is the expert in quality control and can help you ensure that products meet industry and company standards.

REDUCED

RISK

FKI can help businesses reduce risk by freeing up capital and not having to invest in expensive equipment or hire additional staff.

RECYCLING IS BIG AT FKI

A well-managed recycling program should become a part of your company’s DNA. A properly run “Green” program will help save our environment, save energy, decrease production costs, and have the bonus of winning over new clients. Every ton of recycled steel saves our environment by using less than 30% of the energy required to make the steel from scratch. Recycled aluminum saves over 90% of the energy used to produce aluminum from ore.

In 2023, FKI recycled over 5,000 tons of stainless steel, carbon steel, and aluminum. Much more work is ahead, and our “Green” work will continue to make FKI a better place for our employees, customers, and the environment.

OUR HISTORY

40 Years’ Experience

Over 1.77 Million Sq. Ft of Manufacturing Space

5 Countries

3400 Employees Worldwide

ISO 9001-2015

• 1984 – Produced OEM computer chassis.

• 1985 – Hongkai Optoelectronics Co., Ltd. was established, mainly manufacturing automotive components.

• 1990 – Purchased 1000 hectares pyeong of Hongkai industrial land in Taipei.

• 1990 – Awarded a contract with the French government for manufacturing POS systems.

• 1991 – Set up an R&D department with an international marketing team and develop Hongkai Industries’ electronic production line.

• 1994 – Founded FKI USA.

• 1995 – Purchased 1000 <> pyeong on the first floor of the AOC factory office building in China and the Far East.

• 1996 – Acquired land in China and started construction for the DG factory.

• 1997 – Purchased electronic and mold production equipment at the Dongguan plant.

• 1997 – Hongxin Plastic Products Factory (now Tengxiang Precision Plastics Dongguan Co., Ltd.) was set up in Dongguan.

• 1999 – Installing a fully automatic mechanical operation system and improving the factory environment.

• 2000 – Purchased 146000,<> square meters of land in Wujiang, Jiangsu Province, and established Wujiang Hongkai.

• 2000 – Hongda Products Factory (now Hongda Paper Co., Ltd. and Hongda Paper Products Co., Ltd.) was set up in China.

• 2001 – Hongkai Mould Center (now Yuxiang Precision Mould Co., Ltd.) was set up in Dongguan China.

• 2002 – Established SMT and DIP electronics divisions in Dongguan, China.

• 2003 – Dongguan set up Hongxiang Precision Electronic Technology (Dongguan) Co., Ltd., specializing in the production of various types of wire harnesses.

• 2003 – Dongguan China transformed and upgraded from a pc-chasss manufacturer to server and workstation enclosures.

• 2004 – Set up LCD R&D team and a new assembly line.

• 2005 – Dongguan China Construction and expansion of 1,2-level dust-free composite production equipment,

• 2006 – Dongguan China Hongkai expanded the plant, increased the automatic production line of manipulators, and significantly increased the manufacturing capacity of optoelectronic hardware components.

• 2007 – Established Jiexin Precision Plastic Steel Mould (Dongguan) Co., Ltd. in Dongguan, specializing in the research and development, design and manufacture of plastic molds, as well as the manufacture of injection molding components.

• 2007 – Optoelectronic precision plastic components.

• 2008 – Dongguan Hongkai has won the title of “Huangjiang Town Taxpayer” for three consecutive years.

• 2009 – Set up Hongkai Thailand factory in Chonburi, Thailand to serve customers in Southeast Asia Dongguan Aiwang Electronic Technology Co., Ltd. was established, specializing in the production of wireless mouse, functional keyboards, and multi-function wireless remote sensors.

• 2009 – Dongguan China Hongkai won the title of “National High-tech Enterprise”.

• 2010 – Kaijun Optoelectronics Technology (Suzhou) Co., Ltd. was established, with vacuum coating technology as the core technology to carry out multi-angle operations.

• 2010 – Overseas bases were added and Hongkai Thailand Plant was established in Thailand to handle sales in Thailand.

• 2010 – Kaiwei Optoelectronics Technology Co., Ltd. was established to officially step into the touch industry.

• 2014 – The original Hongkai Industry Co., Ltd. was officially renamed as “Hongkai Optoelectronics Co., Ltd.”

• 2019 – Hongkai Thailand plant introduced 1700,<> tons of stamping equipment.

• 2020 – Hongkai Thailand plant completed and added a new paint production line.

• 2021 – The Hongkai Thailand plant added a spot welding production line.

• 2022 – Hongkai Optoelectronics purchased 7 sets of stamping equipment to increase production capacity to serve customers.

• 2023 – The Hongkai Thailand plant added a plastic injection production line and passed the Business Responsibility Alliance (certification)

THE FKI ADVANTAGE

QUALITY &

CERTIFICATIONS

LEARN MORE

GLOBAL LOGISTICS &

PLANNING

LEARN MORE