EXPLORE THE CAPABILITIES

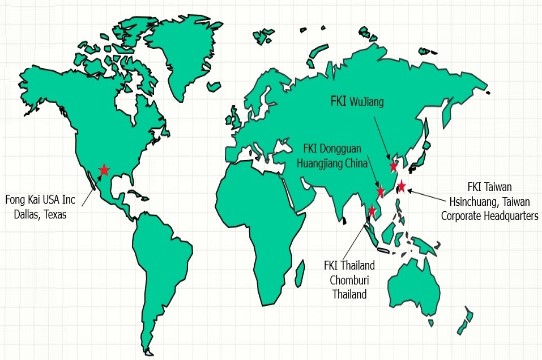

GET STARTED TODAYFKI is a fully integrated family of global mechanical product manufacturing companies. We support Fortune 500 companies in all phases of the process, including design, tooling fabrication, metal stamping, plastic injection molding, finishing, assembly and integration, and logistics. Working with FKI gets you great value and reduced risk. Every day when you walk through your home the probability is high that you will be interacting with components that FKI had a role in helping manufacture. Our client list includes all major US Appliance Manufacturers and several global clients as well. Our team is positioned to support consumer-ready and B2B sub-assemblies for the following product groups:

METAL COMPONENTS

Metal components improve the aesthetic appeal of most appliance products and align with current design trends. Metal offers durability and strength, and can resist wear far beyond many other materials. With our extensive experience, we can collaborate with our customers to develop cost-effective, high-quality components that exceed their specifications.

CAPABILITES

• Over 620 metal stamping presses worldwide.

• 60 Ton up to 2000 Ton

• Presses Beds up to 72″ x 177″

• Progressive & Transfer Stamping

• Class A Cosmetic products

• Specializing in Deep Draw stamping of larger components

• In-House Tooling Build & Maintenance

• US Qualifications available to reduce overseas travel of Engineering Resources

• World-class manufacturing from multiple locations overseas or from our US facility

• All our stamping facilities are certified (ISO 9001) 2015 or better.

ADDITIONAL SERVICES INCLUDE:

• Assembly, Wet and Dry Coatings, Printing, Tapping, Over Coating, Deburring, Plating, and PVD Coating

OEM PRODUCTS

Refrigerator Doors, Control Panels, Oven Door Skins,Cosmetic and Structural Panels, Liners, Cook Tops, Housings, Warming Pans Drawers and Liners, Oven Fan Housing covers, Decorative Trim Panels and Accessory covers, Stainless Control Panel End Caps, Frames, Oven Liners and Drawer Liners, Washer Front, Top and Door Panels, Sinks, Dryer Front and Side Panels, High Speed Dryer Motor Mount and Assembly, Pans, Covers, Lids, Trim, Brackets & Bases, Basins, Tanks, Trays, Wells, Chambers, Canisters, Containers, Shields, Enclosures, Reservoirs, and Basins.

MATERIALS

• Stainless Steel

• Aluminum

• Cold Rolled Steel

• Pre coated Steel & Aluminum

• Electro- Galvanized

• Aluminized Steel

• Enameled Steels

• Bright, Brushed or Mill Finish

• High Strength Low Alloy Material

CLASS A COSMETIC

REFRIGERATOR DOOR

CASE STUDY

When a large appliance manufacturer wanted a unique stainless steel door FKI was called to develop a solution. With our extensive experience in the industry and creative engineering group, we developed a solution that would accomplish the task within the budget. Our team worked directly with the mill to re-engineer the material that would meet the cost, formability, and cosmetic requirements. The new stainless formulation allowed the metal to perform as the customer wanted and made a perfect door.

After development and initial production in our Texas facility, we transferred the tooling to the appliance manufacturing plant for mass production.

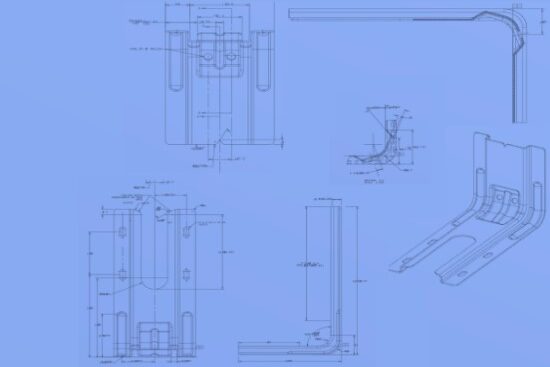

FORMING DIAGRAM

SUPPORTING DEVELOPMENTS

• Complete Turnkey Project Management

• FKI can support Multiple Tool Package Developments from internal and external suppliers/customers

• Virtual Design Review

• PPAP- US Qualifications Available to Reduce Overseas Travel of Engineering Resources

• Welding, Test Fixture, and Jig Development in Accredited Certified Facilities

• Simulation Validation and Reporting

• Laser Welded Fabrication

• Build to Print

• Weldments and Assemblies

• Utilizing Fully Licensed 3D CAD software

• Zeiss CMM with Calypso

• Hexagon Laser Scanning and PC Dimis inspection software

PLASTIC COMPONENTS

Injection Molded plastic components are used extensively in appliances to improve their performance, durability and visual appeal. These plastic components are crucial for the appliance industry because they offer many advantages over other materials. Plastics are lightweight, customizable, and enhance the performance of the appliances.

CAPABILITIES

• 400 plus injection molding machines worldwide

• Presses up to 1600 tons

• Sizes up to 85″ LCD Screens and 5KG shots possible

• Class A Cosmetic finishes

• Specializing in High Cosmetic finishes on larger components

• Pad Printing and Silk Screen Processing

• In-House Tooling fabrication & Maintenance

• Overseas Qualifications available

• World-class manufacturing from multiple locations overseas

• All our injection molding facilities are certified (ISO 9001) 2015

ADDITIONAL FEATURES INCLUDE:

Paint Wet and Dry application, Multi Material Multi Shot, Plating and CNC Machining

OEM PRODUCTS

Door handles, Control panels, Housings, Skins, Vent Trims Panels, Liners, Pans, Covers, Trim, Brackets, and Bases

MATERIALS

• ABS – Acrylonitrile Butadiene Styrene

• PE – Polyethylene

• PC – Polycarbonates

• HIPPS – High Impact Polystyrene

• PET – Polystyrene

• PP – Polypropylene

• Nylon

• Proprietary Polymers

HOW IT’S MADE

“When repeatability, and large quantities are required then progressive metal stamping is usually the best alternative.”

Here is an example of an anti-tip bracket used to prevent appliances, especially ranges and refrigerators from tipping over due to excess weight applied to the open door. These metal safety brackets secure the appliance to the wall or floor and prevent tipping.

WATCH VIDEO

THE FKI ADVANTAGE

QUATITY &

CERTIFICATIONS

LEARN MORE

GLOBAL LOGISTICS &

PLANNING

LEARN MORE