EXPLORE THE CAPABILITIES

GET STARTED TODAYPAINTING

POWDER COAT

A dry powder is electrostatically applied and cured at high temperature to form an encapsulating plastic coating.

ADVANTAGES

• Powder coat produces a hard and durable finish

• Uniform coating thickness

• More eco-friendly than wet paint and emits fewer VOC.

PVD COAT

Physical Vapor Deposition (PVD) is a high-performance coating used in decorative and durable applications. It will not fade, provides a barrier against damage, corrosion, and tarnishing, and reduces friction.

ADVANTAGES

• Durability

• Versatility

• Uniformity

• Eco-friendly

• Cost-effective

E-COAT

Parts are immersed in a paint bath, and an electrical current is applied, binding the paint to the entire surface. This produces a hard finish that is tougher than conventional paint.

ADVANTAGES

• Harsh environments

• Complete & consistent coverage

• More efficiently than spray techniques

• Water-based, immersion technology

WET PAINT

Wet painting uses a spray gun or brush to apply liquid paint to a surface. It is a traditional method of painting that has been used for centuries.

ADVANTAGES

• Ideal for products that cannot be heated.

• A more comprehensive range of colors available

• Typically, cheaper than powder

• Allows for thinner coats that powder can’t accomplish

FINISHING

METAL

ANODIZING

Anodizing creates an Oxide layer on the surface of metal that improves appearance, wear, and corrosion resistance. Typically, anodizing is done on aluminum, and the finish can be natural, matte, bright, or colored.

ZINC &

TIN PLATE

Zinc coating prevents corrosion from forming on the metal by creating a physical barrier and acting as a sacrificial anode – even when this barrier is damaged.

VIBRATORY FINISHING

Vibratory tumbling is used to remove any unwanted burrs, sharp edges, or rough surfaces from metal parts. This process uses abrasive compounds mixed with parts to remove the unwanted sharp edges.

IMPRINTING & DECORATING

FIBER

LASER ENGRAVING

Laser engraving is a non-contact process that creates a visible mark on a variety of materials. Depending on the focal point settings, it can reproduce highly intricate designs as small as a few microns. Laser engraving is often used to produce very small wording or artistic designs.

UV DIGITAL FLATBED PRINTING

Digital printing uses ultraviolet (UV) light to dry or cure ink as it is printed. Because the ink is instantly cured during printing, you can produce faster with no drying times and ensure a high-quality, durable finish. UV printing is one of the most flexible direct-to-object print processes ever created, and its uses are almost limitless.

4-COLOR PROCESS PRINTING

Utilizes four colors of ink: cyan, magenta, yellow, and black (CMYK) to create a wide range of colors. It is also known as CMYK printing or process printing. The process works by separating the image into four different color values, which are then printed using the four ink colors.

IN-MOLD DECORATING (IMD)

The process involves placing an imprinted decal into an injection mold and injecting plastic. FKI utilizes IMD on many consumer electronics, appliances, automotive, and other products. Produces a high-quality, durable finish that is resistant to wear and tear. It is also environmentally friendly as it reduces volatile organic compounds (VOC).

SCREEN PRINTING

A printing technique that uses a mesh screen to transfer ink onto a substrate, except in areas made impermeable to the ink by a blocking stencil. The process works by separating the image into different color values, which are then printed on to a substrate.

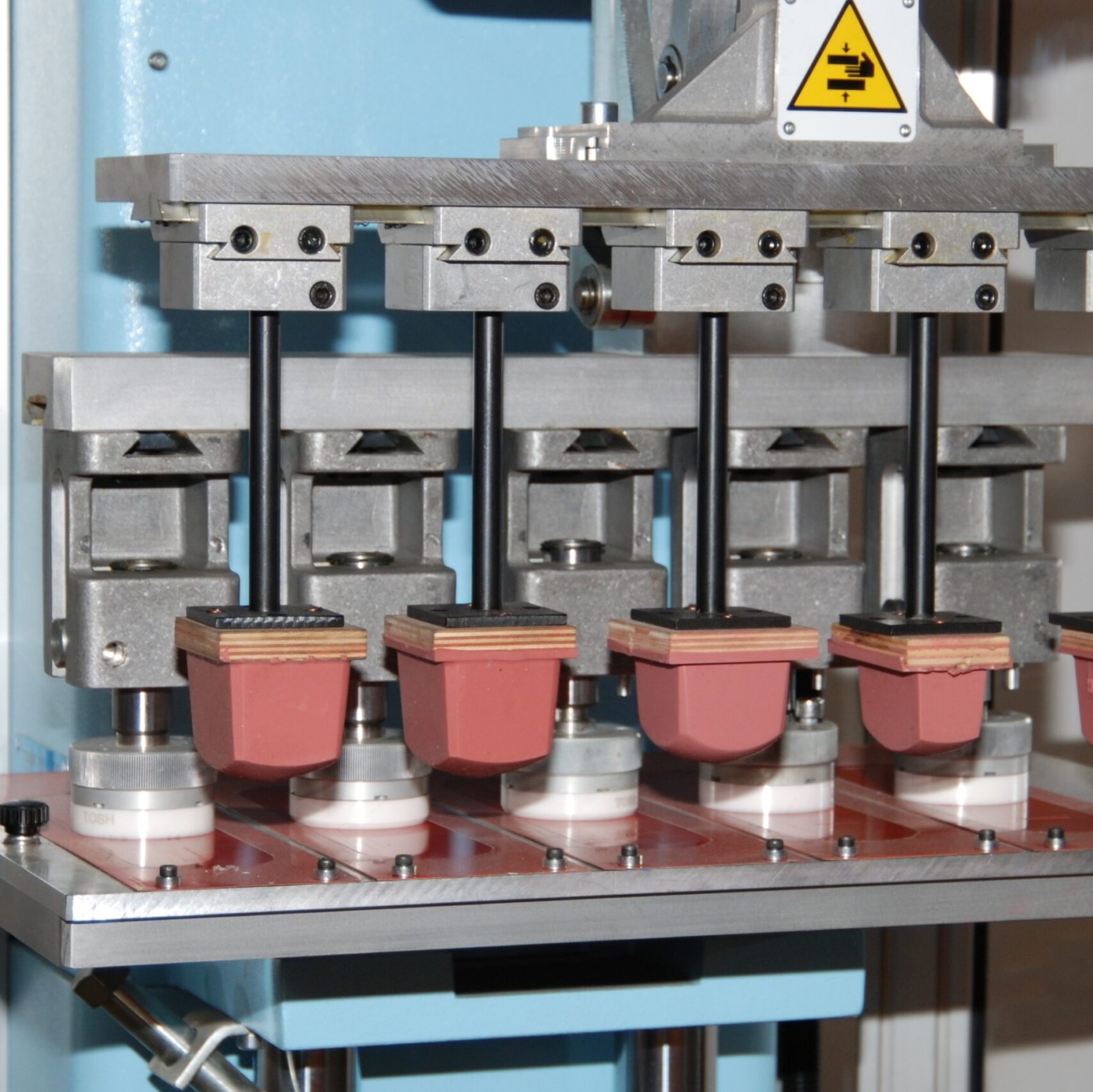

PAD

PRINTING

The process of transferring a 2-D image onto a 3-D object allows printing on various challenging shapes, including curved, hollow, cylindrical, spherical, and textured surfaces. Flexible silicone pads transfer an ink image onto the product being printed.

STAMPING & EMBOSSING

Metal stamping is a process that uses a die to create an indentation or mark on a metal surface. The die is pressed into the metal, leaving an impression of the design on the surface. Embossing, on the other hand, creates a raised design on the metal surface. The metal is pressed between two dies, with the design raised on one die and the other having a recessed design.

HOT

STAMPING

Process that uses heated image molds or stamping dies to transfer metal foils or pre-dried inks onto a surface. The hot stamping machine heats an engraved mold or die, pressing marking foil or ink onto the surface. Hot stamping is a versatile, precise, and efficient method for printing.

PACKAGING

CARTONS & BOXES

FKI can handle the production of all your packaging requirements, including cardboard, cartons, color boxes, manuals, labels, and other paper products. We design, print, and fulfill all your packaging requirements, whether for high-end electronics or traditional industries.

LABELS & DECALS

We offer our customers all the necessary labels, decals, and nameplates in various sizes and materials. Our nameplates can be custom-made from metal, plastic, or vinyl. These labels can be instructions, informational, or a warning.

POLYFOAM & MOLDED PULP

FKI offers a wide variety of economical and environmentally friendly packaging solutions. Molded pulp packaging is eco-friendly and can be recycled, saving time, space, and money.

THE FKI ADVANTAGE

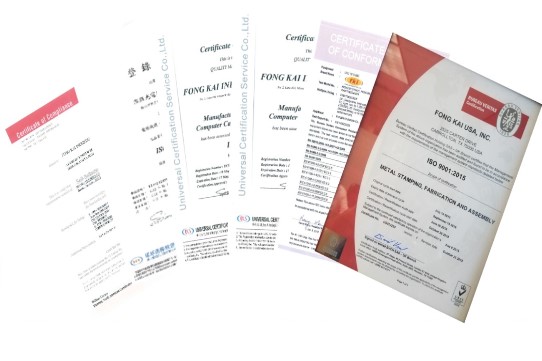

QUALITY &

CERTIFICATIONS

LEARN MORE

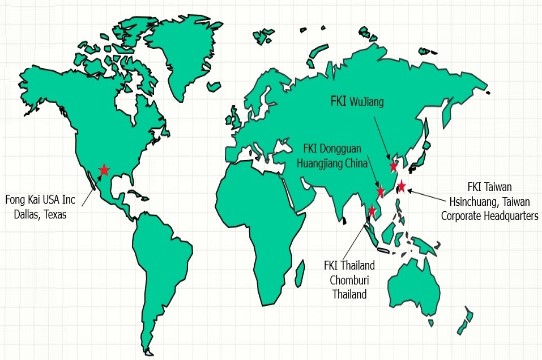

GLOBAL LOGISTICS &

PLANNING

LEARN MORE