EXPLORE THE CAPABILITIES

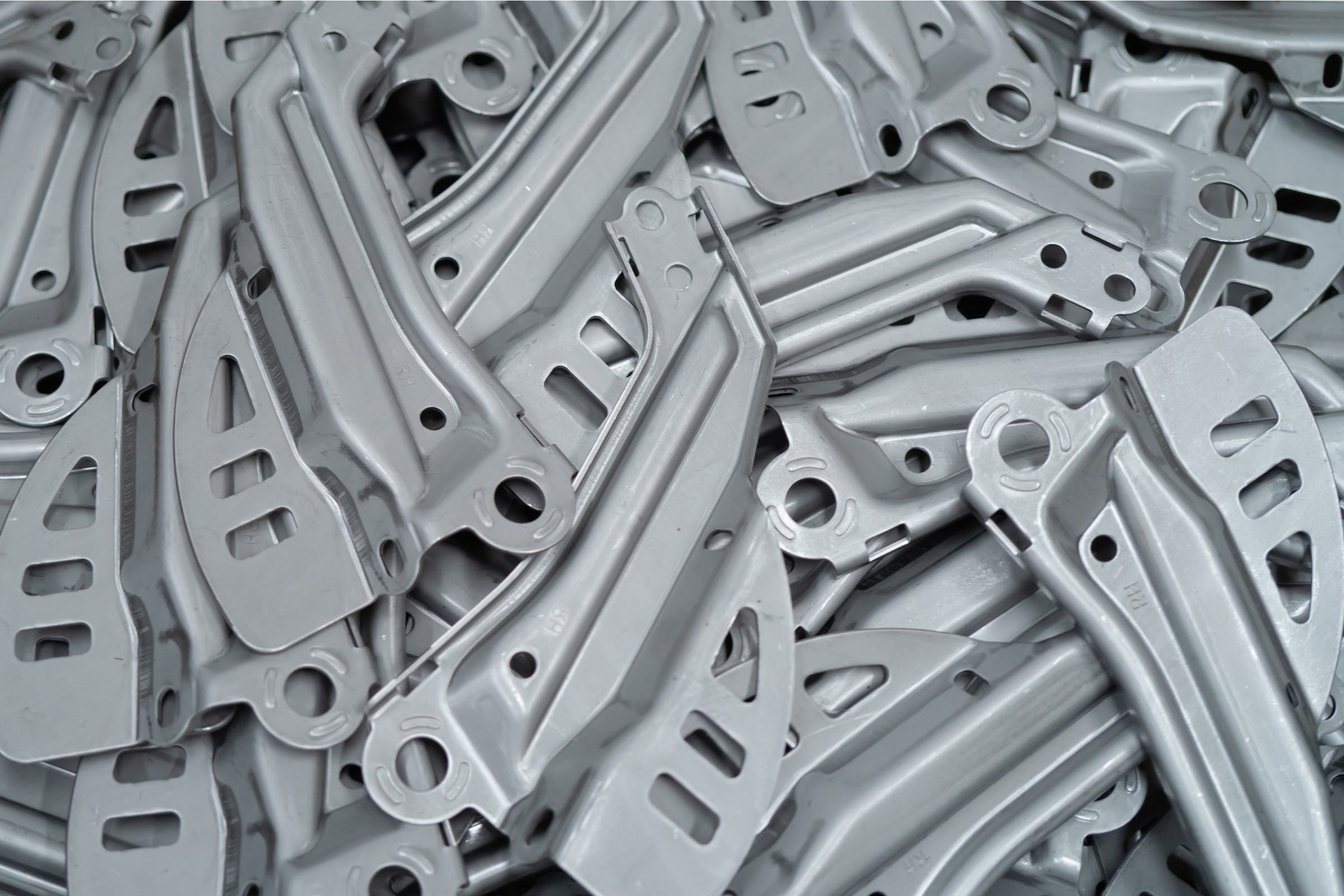

GET STARTED TODAYOur metal stampings produce cost-effective custom parts considering even the smallest details and the tightest tolerances. We build and maintain our stamping tools in-house to the highest standards. FKI provides your metal stamping needs and high-volume contract production for the following industries:

METAL STAMPING EXPLAINED

Pressing or punching either coils or sheets. Metal is pressed between a top and bottom tool to create identical metal parts. Stamping is appropriate for small and large runs and may comprise one or several steps or developments, such as forming, blanking, bending, punching, embossing, coining, and flanging. Material is advanced through a tool, and consistent pressure is applied to create the finished parts. Stamping is a low-cost and high-speed manufacturing process of making large quantities of metal parts.

WATCH VIDEO

620+ METAL STAMPING PRESSES WORLDWIDE

TYPES OF STAMPING

The two most common stamping die types are progressive and transfer die stamping. Both methods should be considered when designing and manufacturing a part. Distinctive design requirements, quantity, and tolerances are evaluated to make a suitable recommendation for the customer.

PROGRESSIVE STAMPING

A process that uses a coil or strip to move parts through a series of individual workstations, each station performing its task on the workpiece.

Learn More

TRANSFER STAMPING

Transfer die stamping cuts the blank and transfers the metal from each station mechanically or by hand.

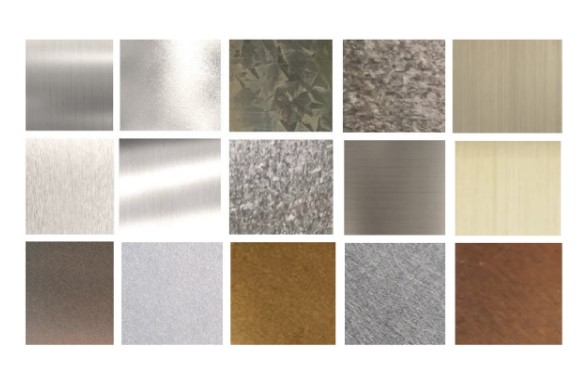

Learn MoreTHICK, THIN, BRIGHT, SATIN & MILL FINISH

We offer metals ranging from .012” to .500” in thickness.

• Stainless Steel

• Aluminum

• Cold Rolled Steel

• Pre-coated Steel & Aluminum

• Electro-Galvanized

• Aluminized Steel

• Engineered Steels

• Bright, Brushed or Mill Finish

• High Strength Low Alloy Material

HOW IT’S MADE

“When repeatability and large quantities are required, then stamping is usually the best alternative.”

WATCH VIDEO

Ready to work with Fong Kai on your next project?

GET STARTED TODAYTHE FKI ADVANTAGE

QUALITY &

CERTIFICATIONS

LEARN MORE

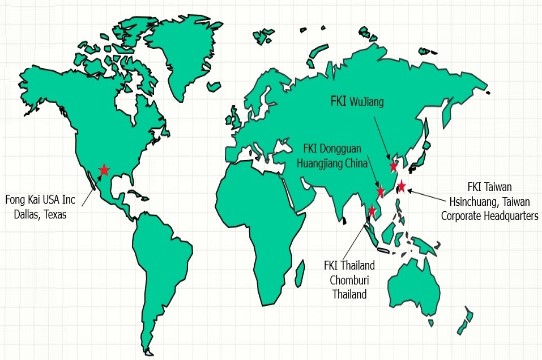

GLOBAL LOGISTICS &

PLANNING

LEARN MORE