EXPLORE THE CAPABILITIES

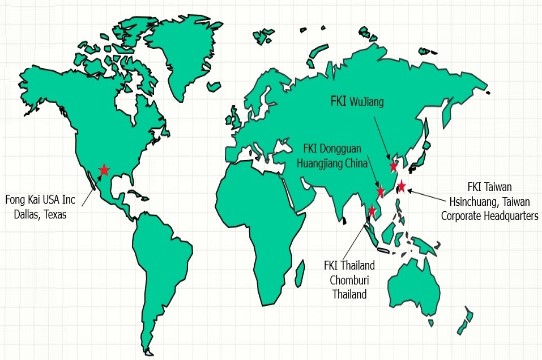

GET STARTED TODAYFKI offers state-of-the-art sheet metal fabrication in five countries and multiple plants. We strive to deliver quality products at an economical price. Utilizing our talented staff and top-notch equipment, we can accurately produce simple or complex geometric parts that meet your needs. We have multiple press brakes as large as 18ft. in length and 440 tons. Our Fiber laser can accommodate 78” x 157″ sheets and up to 12,000 kwh. In addition, we weld, paint, finish, and assemble for the following industries.

OUR FABRICATION PROCESS

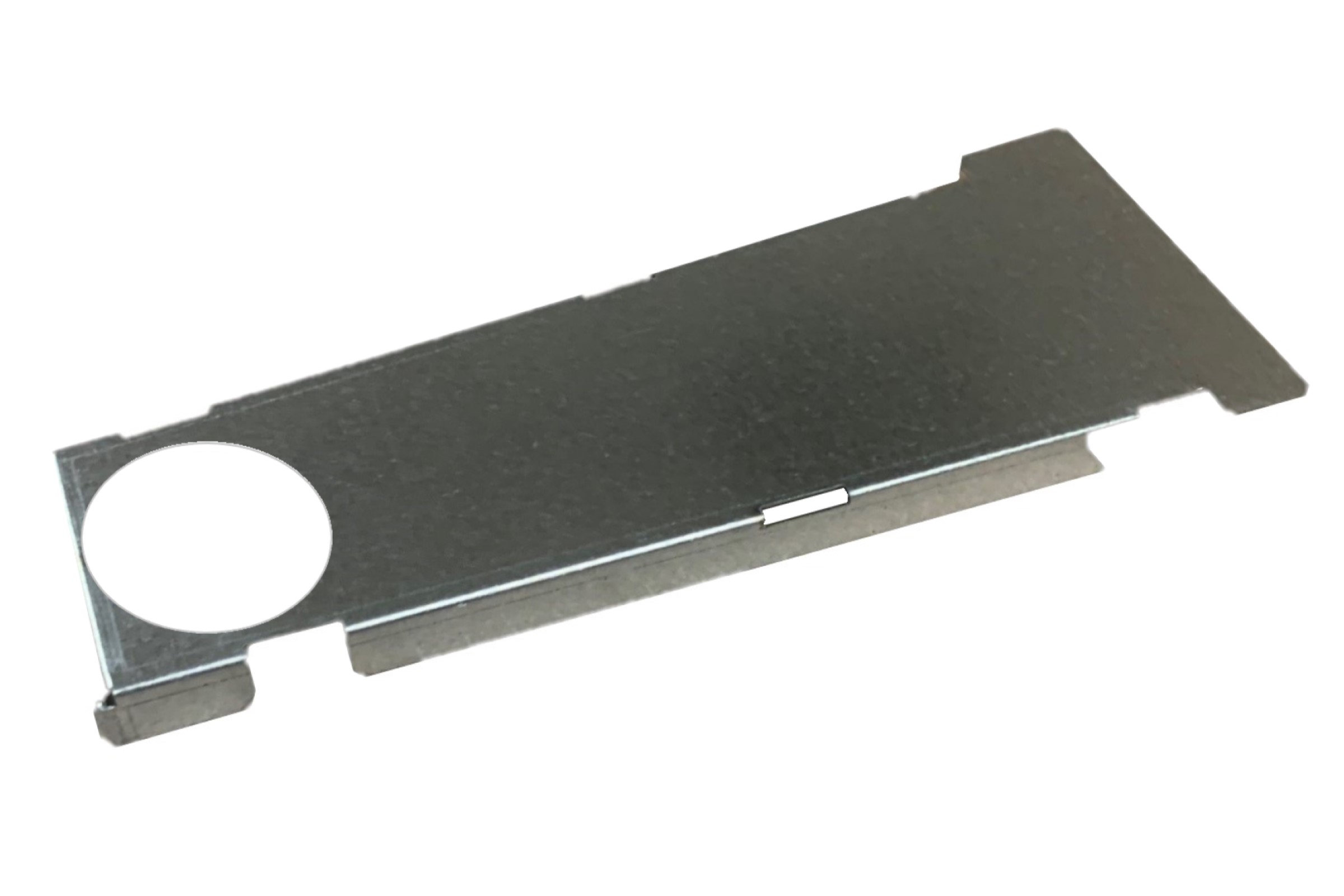

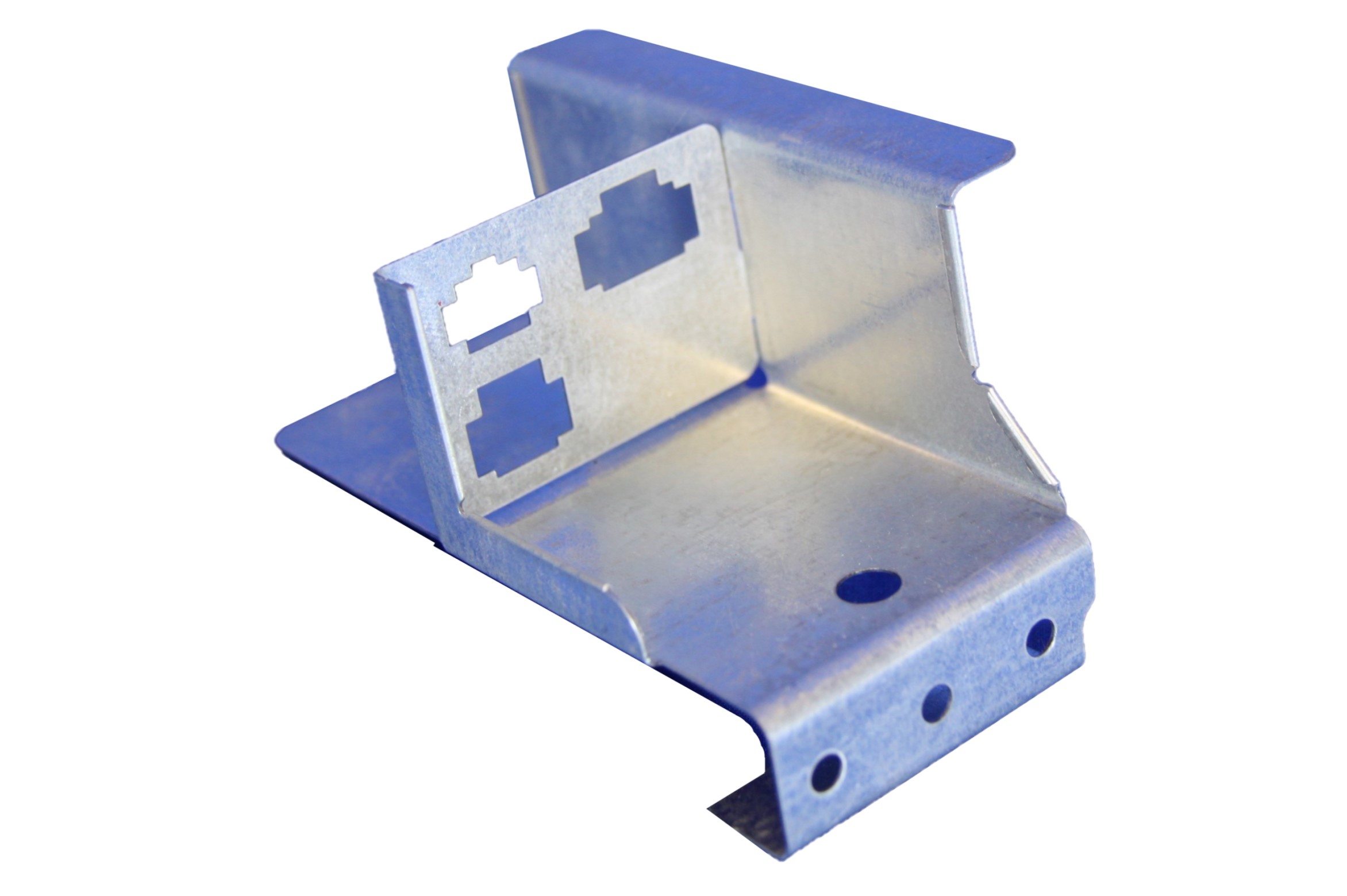

PRESS BRAKE – FORMING AND BENDING

We utilize all three types of press breaks in our production: mechanical, hydraulic, and electric. The bending and forming process is assisted by a punch and die set that clamps the metal and then applies force to create the proper bend or shape.

LEARN MOREADVANTAGES

• Ideal for smaller volume production

• Highly accurate, but not as accurate as stamping

• Flexibility in adjusting tools & dies

• Speed and flexibility

WELDING

TYPES OF WELDING

• Gas Metal Arc Welding (GMAW/MIG)

• Gas Tungsten Arc Welding (GTAW/TIG)

• Shielded Metal Arc Welding (SMAW)

• Flux Cored Arc Welding (FCAW)

ROBOTIC LASER WELDING

Laser welding is a process that uses a highly concentrated beam of light to melt metals or thermoplastics and join them together. Laser welding uses a highly focused beam of light on a very tiny spot so that the area under the laser beam absorbs the light and becomes highly energetic.

ADVANTAGES OF LASER WELDING

• Speed and flexibility

• Deep, narrow welds

• Total heat input is low compared to traditional welding

• Less distortion

• Less heat

• Suitable for an assortment of materials

• Versatility

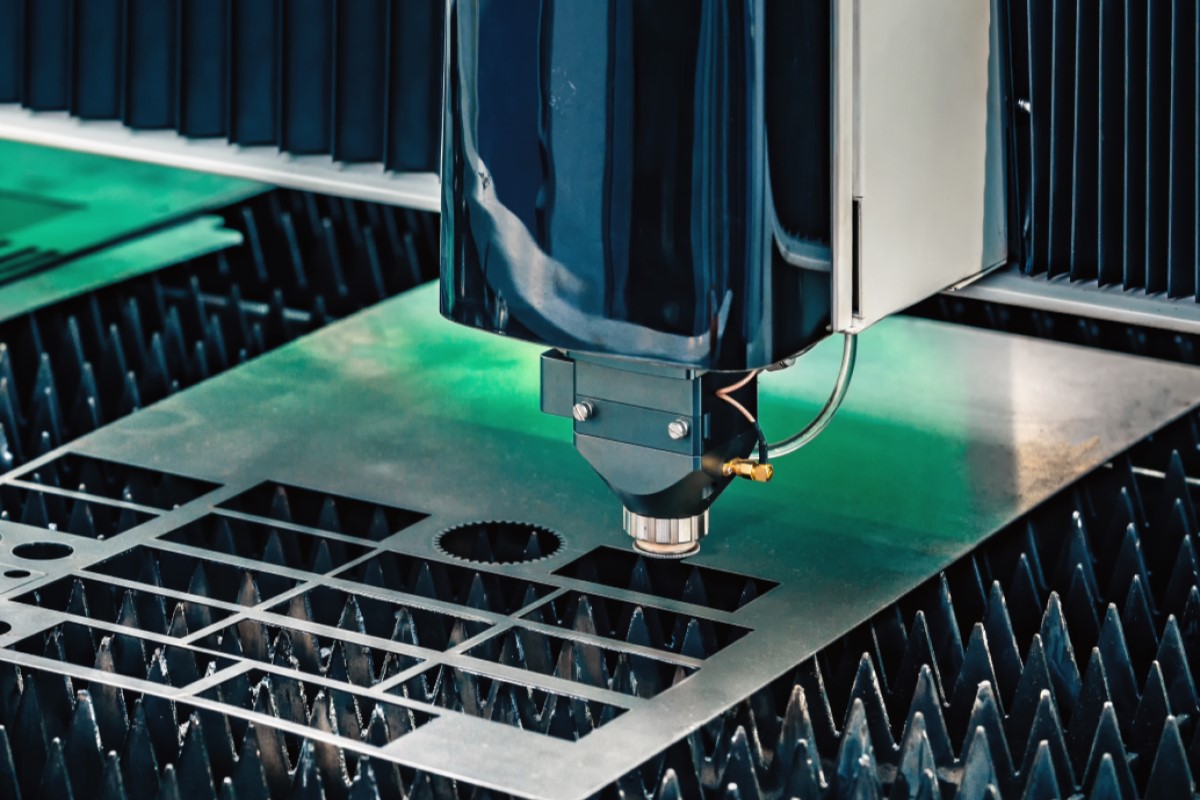

FIBER LASER CUTTING

• 6,000 kwh & 12,000 kwh

• Cutting up to 78″ x 157″

• Fast cutting speeds

• Tight Tolerance

• Complex shapes

• No tooling required

• Quick turn prototypes

• Cost-effective manufacturing.

• Burr-free cuts

PLASMA CUTTING

Plasma cutting is affordable, fast, and efficient for cutting metal. It is accomplished by using a controlled high-velocity stream of ionized gas to slice through metal in a controlled fashion. Plasma cutting doesn’t work with all materials, though it does have a wide range of capabilities with various types of metals.

ADVANTAGES

• Fast production time

• Can cut any conductive metal

• Can penetrate thick metals rapidly

CONSIDERATIONS

• Holes must be equal to or larger than the material

• Plasma-cut edges have an oxide layer

• Tight tolerances are complex and should be avoided

• Plasma cut edges will have some draft

CLEANING, PAINTING, & FINISHING

Our overseas facilities have wet or dry paint systems for decorating metal and plastic. Our team can help you decide which method is best for your product.

PAINT, POWDER COATING, E-COATING

• Wet paint is more straightforward to color match than dry paint

• Wet paint is more cost-effective

• Dry paint is more uniform in coating thickness

• Dry paint is more eco-friendly than wet paint

• Dry coating produces a sharper, more detailed finish

PVD COATING

Physical Vapor Deposition (PVD) is a high-performance coating used in optical applications. It is decorative and durable. PVD provides a barrier against damage and reduces friction, corrosion, and tarnishing. Therefore, it is an excellent choice for decorative finishes that will not fade.

ADVANTAGES

• Durability

• Versatility

• Uniformity

• Eco-friendly

• Cost-effective

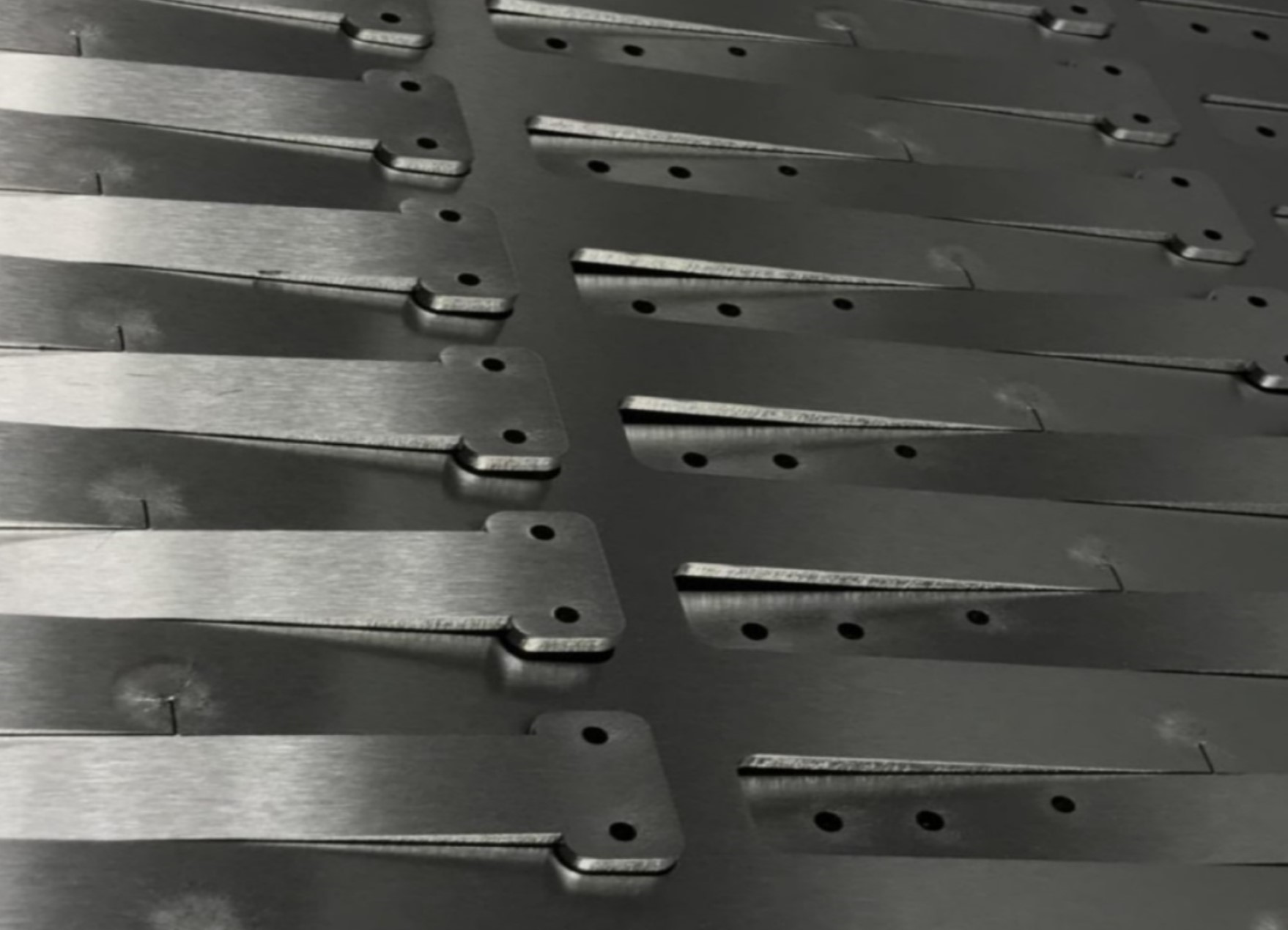

FASTENING & HARDWARE

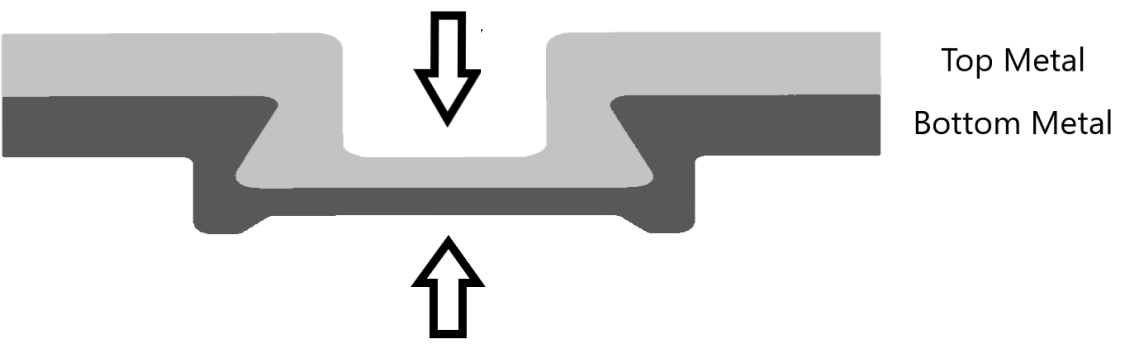

JOINING OR CLINCHING

Sometimes welding, rivets, or screws are not the best alternative when joining metals. A cold-forming process can produce a connection using a punch & die. The top metal is forced to spread outward within the die, providing a high quality, durable, long life expectancy.

INSERTS & ASSEMBLY

We utilize thousands of different fasteners and electronic hardware in our manufacturing. Hardware can be made of alloy steel, stainless, or various metals. Just let us know what you need, and we can even provide MIL, DRFA compliant or certified materials of different Bolts, Inserts, Locking Nuts, Nuts, Washers, Pins, Shoulder Screws, Sockets, Set screws, Retaining Rings, Rivets, Fasteners, Spacers, Standoffs, Studs and more. We can also work with custom fasteners and provide either inch or metric sizes.

MATERIALS

THICK, THIN, BRIGHT, BRUSHED OR MILL FINISH

FKI manufactures simple to complex products using an assortment of metals ranging from .012” to .500” in thickness.

• Stainless Steel

• Aluminum

• Cold Rolled Steel

• Pre-coated Steel & Aluminum

• Electro-Galvanized

• Aluminized Steel

• Enameled Steels

• Bright, Brushed, or Mill Finish

• High Strength Low Alloy Material

THE FKI ADVANTAGE

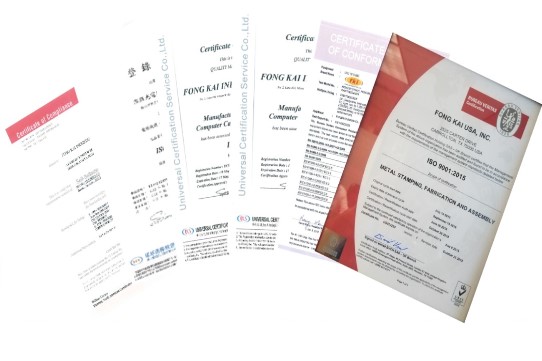

QUALITY &

CERTIFICATIONS

LEARN MORE

GLOBAL LOGISTICS &

PLANNING

LEARN MORE